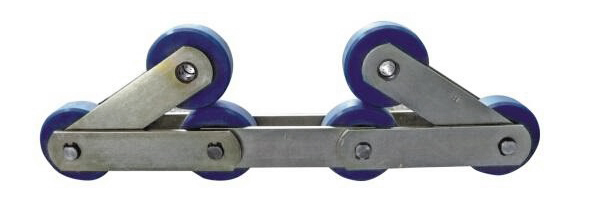

The replacement of the escalator step chain is a complicated work. but it is also the main part of the overhaul and is one of the few complicated technical tasks. First of all, put the escalator on the maintenance, use the maintenance switch to control the operation of the escalator up and down, so that turn the bottom pit to remove all the steps. The process takes about one day for two people. Fixed one day after removing the steps. Prepare the tools needed to remove the large chain of steps, and meanwhile, prepare the new step chain and the big chain breaking from the back-end removed to the outside of the escalator large frame, a new escalator large chain from the back-end installation, you need to use the guide chain after idling around big chain to make it work on constant track route. Such a good step after adjusting both sides of the rear end of the tightening spring screw can be declared completed. Here must reminder our customer that the escalator chain wheel of the step cannot be replaced individually but must replace the whole set step chain. Because of the left and right chains need to be matched, so we need to replacement for both sides together.

How to replace escalator step chain and chain wheel?

Replacement steps as following:

- Determine the number of step sprocket to be replaced, preferably in accordance with the whole chain

- Remove the inner and outer cover and apron board of the left and right straight-line section of the lower end, about 6 meters in length.

- The steps on the chain need to be replaced for removal.

- Move part of the chain that needs to be replaced to the position of removing the inside and outside cover plate and apron plate.

- Loosen the lower end of the ladder chain and tighten it.

- Use special components (or wire) to fix chains that do not need to be removed.

- Remove and replace the escalator step chain.

- Tighten the cascade chain after replacement.

- Install the steps and correct them.

- Install other removal parts.

- Test run