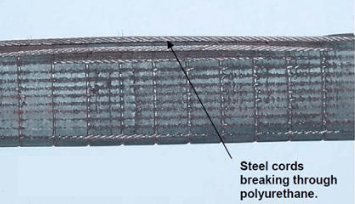

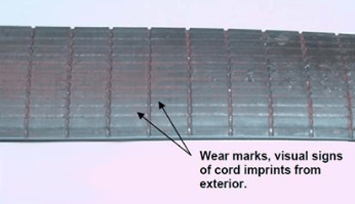

OTIS GEN2 elevator traction refers to the scrap basic standard of steel belt.

1. The design life of the steel belt is 20 years, which is 2-3 times of the traditional steel wire rope. It is recommended to conduct a comprehensive appearance inspection of the steel belt at least once a year during the design life cycle of the steel belt.

2. If there is no abrasion or damage to the steel core in the cladding layer and the steel belt real-time monitoring alarm device without abnormal alarm, then the steel belt will be recommended to be scrapped after 20 years of use.

3.Such as found in the routine maintenance of steel belt real-time monitoring alarm device has the abnormal alarm but did not stop running , need to check the steel belt monitor alarm device whether it is abnormal. If the belt monitor alarm device itself without exception, we suggest replacing the steel belt immediately.

4. If the steel belt monitor device alarming in real time and the elevator stop running. We should scrap and replace the steel belt immediately if the elevator does not re-serve in any way.

5. One of the following situations should be forced to scrap and replaced.

Tag Archives: elevator

Elevator accessories – selection of steel rope

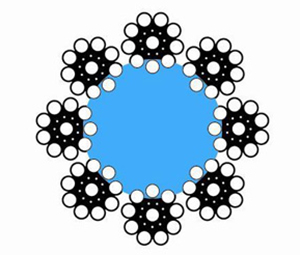

In order to be safe, the hoisting steel rope of the elevator is used with special or no. 1 steel wire, and its steel wire diameter is limited to between 0.3 and 1.3mm. The hoisting rope of the elevator is seru (X type) and warrington (W type). At present, the domestic elevator generally uses the silu-style 8 or 6 steel rope hauling steel rope, among which 8X(19) has more applications.

Elevator parts – selection of steel rope

1. Example of steel rope mark identification.

1000kg of passenger elevator to the rated load, for example, SCH elevator traction rope with 8 X (19) – 16-140 right hand in, eight for the line number of shares, X is west lu type, (19) for each strand of wire number, 16 for SCH elevator traction rope nominal diameter (mm), and 140 for SCH elevator traction rope tensile strength (KGF/was), the right to pay for steel wire strand and strand in line right direction twist system. The domestic SCH elevator traction steel rope is right handed.

2. Steel rope core

SCH elevator traction steel rope was used for the oiled fiber rope, rope support and fixed rope stock position so as to improve the contact between the steel rope, slow down the impact load, fuel storage pool role for SCH elevator traction steel rope of lubrication oil source for a long time, make good lubrication performance of the steel wire.

3. The structure and characteristics of the siu-type (X) SCH elevator traction steel rope.

SCH elevator traction rope in strands of the cross section of a share to 1 + 9 + 9, namely core plus the first layer and the second layer, a total of 19 roots of steel wire: center wire 1 root, φ1.2 mm, inner layer steel wire 9 root, φ0.6 mm, outer wire 9 root φ1.05 mm. The outer diameter is larger than the inner diameter, so it is also called the outer rough elevator to drag the steel rope. It is characterized by the same number of steel lines in the inner and outer layers of each share, but the diameter is different, the outer layer is embedded in the inner cavity of the inner layer, the twisting distance of the multi-layer steel wire is equal, the structure is tight and strong, and it is not easy to open the volume. The outer thick steel wire increases the wear resistance; the inner layer fine steel wire enhances softness, which is advantageous to the sliding of the bending moment, thus improving the flexibility and service life of the elevator traction steel rope. Between the two layers, the steel rope is in contact with the steel rope, and the fatigue resistance of the steel rope is good. The resistance of the steel wire is good, the contact area is increased and the contact stress is reduced.

Elevator heart part — controller

Elevator heart part: controller

Elevator controller main components are: control panel or controller, transformers, bridge pile and capacitance, air switch or fuse, relay and contactor, drive, power cables, signal lines, terminals or connectors and other components.

Three tips warning for Elevator

1. Do not allow to grill elevator door by hands in any condition when it is running.

More than 70 per cent of elevator accidents occur on door system. Why we say that? Anyone who knows the structure of elevator knows that it would be like a trap in front of your feet. There is a risk of shearing, squeezing, and hanging from the inside. So, when you take the elevator, you must see it clearly and then step back, wait for the elevator stop, and then leave the door open.Continue reading

Technical conditions for main parts scrapping of elevators

- Three core components , the host, door machine, control drive system (that is, the panel in the control cabinet and converter) steel wire rope, long service life and can reduce maintenance costs, speed limiter, buffers, safety gear, the three is the most key components in the elevator safety, more than four pieces can consider to import

- Four Spaces: part of the machine room, well road and pit, car part, floor part.

Eight systems: traction system, guide system, cage, door system, weight balance system, electric drive system, electrical control system, safety protection system. - Eight application technologies:

How long does the elevator service life?

How long does the elevator service life?

- Generally speaking, the life of the elevator that the manufacturer promises is 20 years.

- so the elevator service life as normal, generally use ten to fifteen years or so, the working condition and maintenance efforts, do a repair, replacement of a batch of badly worn, obsolete, do not conform to the new rules of the components, with five to eight years, then can do it again on upgrading and replacement of a full range of security components, replace the latest host and control system, capsules and guide rail can preserve, involved in capsules showed what can change, and can continue to use about ten years, eight years later to a whole new ladder.

- Therefore, three years for new, three years for old ,and three years for mended, The elevator service life can be used for twenty-five to thirty years if under good condition. If you are worried about the supply of Elevator Parts or Escalator Parts , you can contact us.