The elevator guide rail not only controls the movement of the elevator car and the counterweight, but also provides strong support for the elevator to be braked when the car has an unexpected overspeed. So elevator guide rail is an important part of elevator running under quality and safety. The quality of elevator running is good, or not, which depends on the quality of elevator installation, and also the quality of elevator guide rail installation depends on the quality of elevator installation. So we will analyze how to install the elevator rail bracket, elevator guide rail with best process for you.The elevator guide rail not only controls the movement of the elevator car and the counterweight, but also provides strong support for the elevator to be braked when the car has an unexpected overspeed. So elevator guide rail is an important part of elevator running under quality and safety. The quality of elevator running is good, or not, which depends on the quality of elevator installation, and also the quality of elevator guide rail installation depends on the quality of elevator installation. So we will analyze how to install the elevator rail bracket, elevator guide rail with best process for you.

Elevator T-rail Lifter, Cheap Elevator T-rail Lifter Supplier, T-rail Lifter Manufacturer, Elevator Guide Rail Installation Tool, Elevator Guide Rail Installation Device, Wholesale Elevator T-rail Lifter, Elevator T-rail Lifter Online, XAA27AAD1, XAA27AAD2

(1) Installation process of elevator guide rail bracket

- 1) If the elevator shaft is brick wall, concrete casting guide rail bracket is generally adopted with a depth of no less than 130mm.

- 2) If the hoistway is brick-concrete-structured or concrete ring beam, the guide rail bracket should be installed on the concrete ring beam.

- 3) If the vertical deviation of the hoistway exceeds the standard, the hoistway should be changed or use the rail bracket spacer for adjustment.

- 4) After the hoistway design is completed, the installation of guide rail bracket for each brand elevator will be different according to actual situation.

- 5) The long guide rail bracket will be selected when the hoistway size is larger than standard drawing.

- 6) The guide rail bracket is processed sequentially according to actual distance between guide rail bracket and hoistway wall. How to local the installation position of rail bracket? The installation position will be located according to center line and auxiliary line of rail bracket, and then do spot welding with level rail gauge.

(2) Installation process of elevator guide rail

- 1) Elevator guide rail and counterweight guide rail that is set with counterweight safety should be fixed on the solid ground base. The pit guide rail base should be kept horizontal, the levelness does not exceed 1/1000, and the height is about 60mm, and which is concreted around leveling with concrete.

- 2) To check the straightness of elevator guide rail and keep it within 1/6000, if the nonstandard guide rail should be adjusted or replaced. Checking the end of tenon whether all right, clear the tenon before installation.

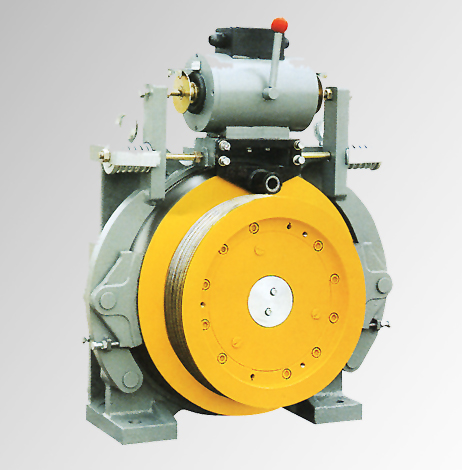

- 3) During elevator guide rail, use the winding machine to lift the guide rail, the last guide rail should be cut according to actual length before lifting.

- 4) After installation of elevator guide rail finished, the guide rail should be adjusted from bottom to top, if where any deviation is, correct it immediately.