Guide rail: a device, such as a groove or ridge made of metal or other material, capable of withstanding, securing, guiding or reducing friction

It should have the following properties:

(1) Guidance accuracy — the accuracy of trajectory guidance. The main factors affecting the guidance accuracy include: geometric accuracy and contact accuracy of the guide, the structure of the guide, the stiffness and thermal deformation of the guide and its supporting parts and the oil film thickness and stiffness between static (dynamic) pressure guides.

(2) Accuracy retention — mainly determined by the wear resistance of the guide rail. The wear resistance is related to the material of the guide, the friction property of the guide pair, the pressure on the guide and its distribution law.

(3) Stiffness — mainly includes the guide’s own stiffness and contact stiffness. It mainly depends on the shape、size、connect mode and bearing condition of guide rail.

(4) Low speed motion stationary — the friction-induced self-excited vibration of guide rail during low speed movement or micro-displacement is easy to occur, that is, crawling. Crawling reduces the positioning accuracy or increases the surface roughness of the work piece

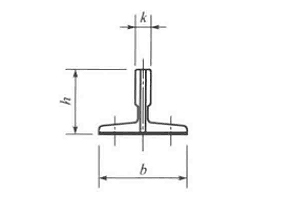

The T Type- shaped guide rail & the hollow guide rail of the guide rail type

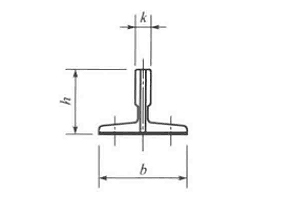

T type guide: its main dimensions and tolerances are shown in the table below. The common guide rail listed in the table and T82/B is the industry size, which is different from the old lift t-guide standard J6 5072.1-1996.

Main dimensions and tolerances of guide rail

| Model and tolerance |

b |

h |

k |

| T75—3/B |

75 |

62 |

10 |

| T78/B |

78 |

56 |

10 |

| T82/B |

82 |

62 |

16 |

| T89/B |

89 |

62 |

16 |

| T90/B |

90 |

75 |

16 |

| T114/B |

114 |

89 |

16 |

| T125/B/BE |

125 |

82 |

16 |

Hollow guide—it is made of steel plate through cold bending (or rolling) into a hollow t-shaped elevator to reuse the guide rail, which can reduce the weight and cost due to its empty characteristics. It satisfies the function of heavy guidance, but cannot bear the clamping force of safety pliers, so it is only used for the weight guide rail without the weight safety pliers and the elevator speed is not high.

The name of hollow guide is composed of class, group, type, feature, main parameter and deformation code.

□– deformation code: A means underside folding, underside straight edge omitted

△– Main parameter code: expressed as per unit weight of guide rail, kg/m

K– Type code: hollow section steel

T — Class group code: t-shaped elevator for reuse guide rail

For example, TK5A represents a 5kg/m t-shaped hollow guide with folded edges