-

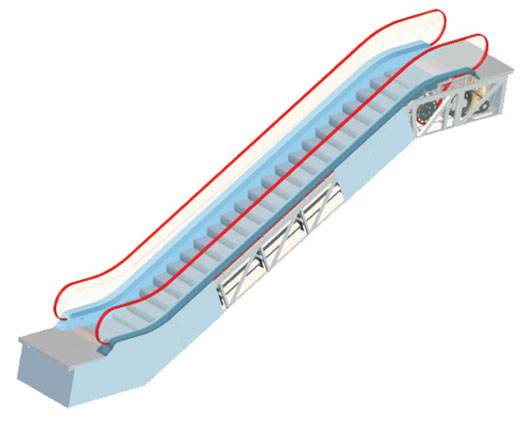

Production principle of escalator handrail belt:

Escalator handrail belt is through to the already have preliminary shape heating raw material, after a period of time under the high pressure heat vulcanization, make raw material molded into a stable shape of the handrail can use for a long time.

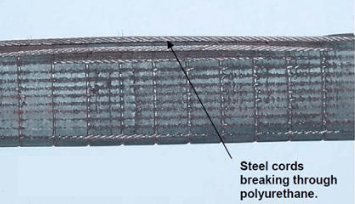

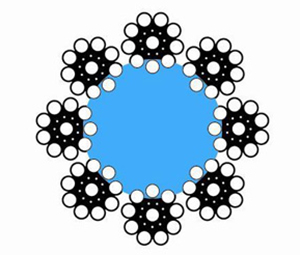

The raw material is in the shape of strip layer, which generally includes organic rubber and plastic layers such as adhesive layer, polyurethane layer, tensile steel wire layer and special adhesion layer on surface. With polyurethane organic matter such as rubber layer is a special spiral screw rubber extrusion type extrusion, while tensile steel wire layer is by cutting machine rolled the wide contain plastic wire length, cutting out by bonding, can turn the layer growth in raw strip. Escalator is common black handrail, with the development of customer demand, began to appear red, green, blue, yellow and so on different color handrail, these armrest different because of mixed with different additives. Different elasticity, different abrasion resistance, different tensile fatigue strength and environmental protection. The escalator handrail can be divided into three parts according to the position: pump station part, main engine part, and mold core linear guide rail oil motor chain drive part.

-

Basic performance parameters of escalator handrail belt:

Automatic handrail with four cylinders total pressure: 100~200 T

Vulcanization time of escalator handrail is: 5~20 min

Escalator handrail belt material vulcanizing temperature : 180 ℃

The escalator armrest belt presses down at a fast speed of: 30 mm /s

The total power of the escalator handrail drive motor is: 22 KW

Escalator handrails with a large vulcanization length of: 3000 mm

The moving speed of the die core of escalator handrail is: 18300-30,000 mm /min

Size of escalator handrail equipment (length, width and height): 12100*1900*2800 mm

The total weight of escalator handrail equipment is: 18 T

-

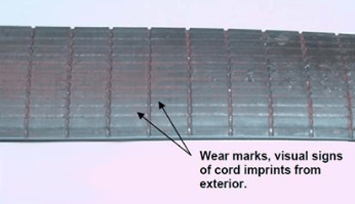

The service life of escalator handrail belt

In general, the indoor escalator handrail belt service life of 10 years or so, outdoor escalator handrail is normally only used 6 years or less time, the escalator handrail will appear wear fracture, in these cases need to do replacement timely.

ELEVATOR VIP supplies all various of escalator handrails, for more please visit here: escalator handrails