In order to be safe, the hoisting steel rope of the elevator is used with special or no. 1 steel wire, and its steel wire diameter is limited to between 0.3 and 1.3mm. The hoisting rope of the elevator is seru (X type) and warrington (W type). At present, the domestic elevator generally uses the silu-style 8 or 6 steel rope hauling steel rope, among which 8X(19) has more applications.

Elevator parts – selection of steel rope

1. Example of steel rope mark identification.

1000kg of passenger elevator to the rated load, for example, SCH elevator traction rope with 8 X (19) – 16-140 right hand in, eight for the line number of shares, X is west lu type, (19) for each strand of wire number, 16 for SCH elevator traction rope nominal diameter (mm), and 140 for SCH elevator traction rope tensile strength (KGF/was), the right to pay for steel wire strand and strand in line right direction twist system. The domestic SCH elevator traction steel rope is right handed.

2. Steel rope core

SCH elevator traction steel rope was used for the oiled fiber rope, rope support and fixed rope stock position so as to improve the contact between the steel rope, slow down the impact load, fuel storage pool role for SCH elevator traction steel rope of lubrication oil source for a long time, make good lubrication performance of the steel wire.

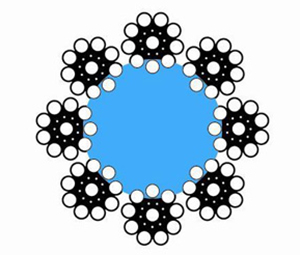

3. The structure and characteristics of the siu-type (X) SCH elevator traction steel rope.

SCH elevator traction rope in strands of the cross section of a share to 1 + 9 + 9, namely core plus the first layer and the second layer, a total of 19 roots of steel wire: center wire 1 root, φ1.2 mm, inner layer steel wire 9 root, φ0.6 mm, outer wire 9 root φ1.05 mm. The outer diameter is larger than the inner diameter, so it is also called the outer rough elevator to drag the steel rope. It is characterized by the same number of steel lines in the inner and outer layers of each share, but the diameter is different, the outer layer is embedded in the inner cavity of the inner layer, the twisting distance of the multi-layer steel wire is equal, the structure is tight and strong, and it is not easy to open the volume. The outer thick steel wire increases the wear resistance; the inner layer fine steel wire enhances softness, which is advantageous to the sliding of the bending moment, thus improving the flexibility and service life of the elevator traction steel rope. Between the two layers, the steel rope is in contact with the steel rope, and the fatigue resistance of the steel rope is good. The resistance of the steel wire is good, the contact area is increased and the contact stress is reduced.