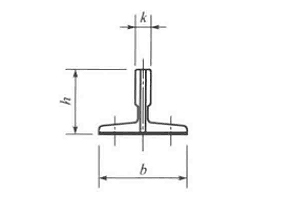

The sill in the elevator refers to the metal horizontal component of the opening part, such as the entrance and exit to the ground. It can also be defined as the metal pedal with groove that enters and leaves the car of the elevator car or floor door. It is installed at the entrance and exit of the elevator, usually under the door plate, and ACTS as the guide device for door plate movement and the load device for entering and exiting cars and objects.

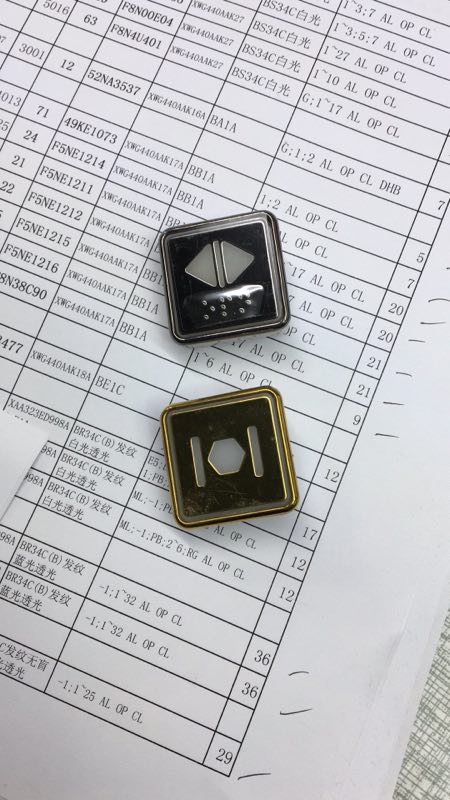

Classification: elevator floor is divided into car door sill and landing door sill

The function of sill: car door sill and landing door sill both belong to the important parts in the elevator door system. They work together with the floor slide block to ensure that the elevator car door does not shake back and forth, playing a safe role. It also serves as a guide.

elevator landing door sill, elevator car door sill, elevator sill guide supplier, elevator sill guide manufacturer, elevator sill guide exporter, elevator sill guide factory price, wholesale elevator sill guide, cheap elevator sill guide for sale, buy quality & original elevator sill guide, elevator sill classification, elevator sill installation, elevator sill structure, elevator door system sill, elevator part sill

Landing door sill Installation technology

- Put down two floors of doors from the upper sample frame to install the standard line. For the height of the building, the guide rail can be used to fix it in the state of natural static, and the lower end is still tied with iron wire to the lower sample frame.

- Draw the net door center line and the net door width line on the pedal according to the center of the floor door pedal and the net door width line.

- Determine the length of the door pedal according to the net width of the door.

- Determine the standard height line of floor sill in consultation with the civil engineering unit, so that the floor sill is higher than 5-10mm after decoration.

- Make the mounting bracket of the door pedal, and take the two standard stitching lines of the door sill as the reference re, and fix them on the precise alignment and positive guide rail after correction.

Each floor entrance shall be provided with a sill with sufficient strength to withstand the load of entering the car through it. The strength of floor sill is directly related to the load of car. The higher the load of elevator, the higher the strength of floor sill should be. We rarely see the situation of fracture or maintenance due to insufficient strength of the sill. However, due to the lack of specific standard, the deformation of the sill is often unable to judge whether it is qualified or meets the use conditions. The most extreme case is that the passenger ladder is used to transport the goods by the hydraulic forklift when the cargo is transported by the cargo ladder. It is calculated at the rate of 1.1 times of the maximum load, and half of the load at the weakest initial action of the landing door sill at the entrance and exit. Check the deformation of the sill, generally permanent deformation is not more than 2mm, should be considered qualified.