1 LMCSS-MCB JFA26801AAF002 MCS 321 MCS321M-OVF30 SYSTEM

2 RCB II GHA21270A2 PLUG OUT

3 RCB II GHA21270A1 PLUG UP

4 DCSS VE GDA24350BH1

5 MAGNET SWITCH GAA177HB1 PNP

6 MAGNET SWITCH GAA177HB2 PNP

7 MAGNET SWITCH PNP

8 MAGNET SWITCH GAA177HB4 PNP

9 MAGNET SWITCH GAA177HB5 PNP

10 MAGNET SWITCH GAA177HB6 NPN

11 SPBC Board For Otis Gen2 GAA26800KB1

12 STEEL BELT SLIDER GAA385GX1

13 ENCODER PKT1030A-1024-J3OF JAPANESE TYPE REPLACED

14 ENCODER TAA663A1 ORIGIN

15 LB II

16 GPCB EA610XJ1

17 GAA24350BH1

18 RS5 GAA23550D1 ORIGIN

19 RS5 GAA23550E1 CHINA

20 RS5-C3

21 SIWEI INVERTER PCB XAA616BR1

22 SIWEI INVERTER PCB OTIS XIZI2000 MODEL-OH-5000

23 STEP GAA21640 1000/800

24 506 DRIVING CHAIN DUPLEX

25 STEP DEMARCATION GO455G1/GO455G3/GO455G4 GO455G5/GO455G11/GO455G12

26 TEST TOOL GAA21750S2 GAA21750S1/GAA21750AK3

27 506NEC BRAKE G0222P1

28 V-BELT GAA717N1

29 13VTR MACHINE

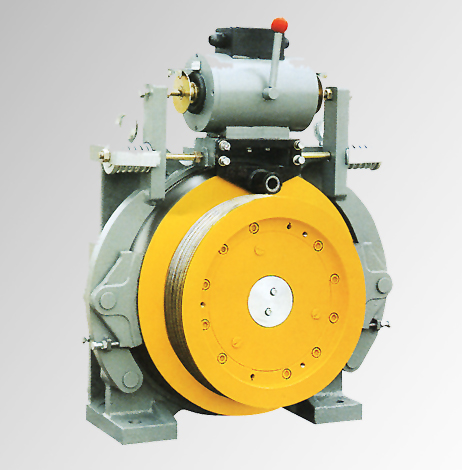

30 510 FRACTION WHEEL GO265AH OD=781mm ID=90mm BEARING:6210Z

31 HANDRAIL GUIDE STRIP GAA50AHA1 L=6000mm

32 SSGD-1L (NC)

33 HANDRAIL HEAD ROLLER GO2215P4

34 ROLLER PIN GO465BA1

35 GECB-EN GBA26800LC2/GDA26800LJ2

36 FRACTION WHEEL DAA265NNN1 456mm

37 506 SPROCKET WHEEL GAA195NV1

38 LOCK ROLLER FAA456RA1

39 AT120 DOOR POWER FAA24350BM1

40 GEN2 Head Reader with SAC (OVF20) GAA22439E12

41 18ATF Machine Encoder AAA633L1 Chinese type replaced 3 ways

42 ENCODER RKT1040-1024-C15C

43 HAIRY SLIDER FAA470E1

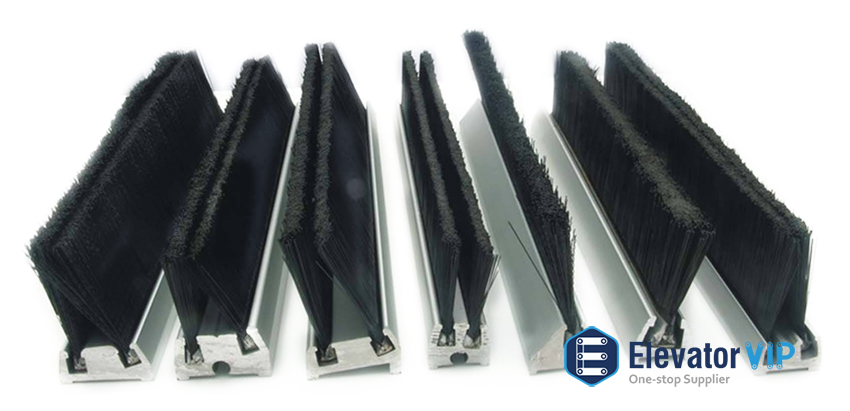

44 506 TESION CHAIN GAA332Z4 WITH STEEL TUBE

45 MCB3X GCA26800KV3

46 MCB3X GCA26800KV7

47 DOOR ROLLER FAA5394A50 55*16.5mm

48 INLET COVER GAA384JY1

49 INLET COVER GAA384JY2

50 INLET COVER GAA384JY3

51 INLET COVER GAA384JY4

52 INLET COVER GAA384JY5

53 Pulse transducer GAA20401A515

54 506 TESION BOX GO385EP1

55 Interlock switch GAA177GF1

56 Interlock switch GOA177BX4

57 Interlock switch GAA177HL1

58 Interlock switch GAA177HL2

59 Interlock switch GBA177HK1

60 Interlock switch XCXN2108P20C

61 Interlock Brake switch GBA177FG1

62 Key switch start-up ASW0335 IND CONT 858T

63 Interlock switch GBA1776Y1

64 INLET PLATE GAB438BNX1

65 INLET PLATE GAB438BNX2

66 STEP ROLLER GAA290CB2 76.2*22 Hole Diameter= 20.1mm

67 OPERATION PANEL GAA26220AM1

68 OPERATION PANEL GAA26220AM2

69 OPERATION PANEL GAA26220AM5

70 OPERATION PANEL GAA26220AM6

71 OPERATION PANEL KEY GAA26220AM500

72 BELT INSPECTION CSB FAA21700F1

73 BELT WHEEL GO2215AB7

74 WWPB-2 (GEN2) WWPDB GAA26810C2(GBA26810A1)

75 OTIS PCB WWPB_2 GAA26810C2

76 CEDES PHOTOCELL

77 DOOR SILL FAA483T1 L=2115mm

78 506NCE MAIN BOARD GAA26800AR2

79 506NCE MAIN BOARD CHIP

80 SPBC II GBA26800KM1

81 OPERATION PANEL GAB26220DB5

82 OPERATION PANEL GAB26220DB4

83 OPERATION PANEL GAB26220DB3

84 FLAT BELT 60mm

85 FLAT BELT 45mm

86 FLAT BELT 30mm

87 AT120 MOTOR FAA24350BL1 FAA 24350BL2

88 506 SPROCKET WHEEL GO2215AB20 OLD TYPE

89 SOM-II GAA26800AL1 GEA26800AL1

90 SOM-II GAA26800AL2

91 RSEB B9693AE1

92 RS14 GAA25005C1 CHINA

93 RS14 GAA25005B1/GDA25006B1 GERMANY

94 GAA26803A1

95 INLET W/BRUSH

96 INLET W/O BRUSH

97 506NCE V-BELT 1900mm

98 506 V-BELT 2476mm

99 510 V-BELT

100 TESION DEVICE B8669B1

101 GUIDE SHOE ROLLER 95mm

102 GUIDE SHOE ROLLER 125mm

103 GUIDE SHOE ROLLER 200mm

104 GUIDE SHOE ROLLER 200mm 2RS

105 LB-II GAA21230F2

106 LB D.9673T

107 MLB A.9673AF

108 CAN(TCBC) GDA26800KA1

109 70AMPS INVERTER BAORD ABA26800RB1

110 LIMITED SWITCH S3-B1370

111 LB-II GFA21230F1 GCA610YW1

112 MCBII W/VCR GCA26800H2

113 Otis Tape head GAA22439E12

114 push button FAA25090A111

115 LIMITED SWITCH LX26-111B

116 HANDRAIL DRIVING GAA26180D2

117 Chick let 369PB1

118 EPROM GAA30328AAG1

119 RATHGEBER 23 TEETH COMB 96003384001

120 Comb Plate G02215W8

121 Comb Plate G0453D1

122 Comb Plate G0453D2

123 Comb Plate G0453D3

124 Comb Plate G0453D4 Left

125 Comb Plate G0453D5 24T

126 Comb Plate G0453D6 23T

127 Comb Plate G0453D7 23T

128 Comb Plate G0457BF11 Power Coat

129 Comb Plate G0457BF12 Power Coat

130 Comb Plate G0A453A1 PROGRESSIVE 18T

131 Comb Plate G0A453A4

132 Comb Plate G0A453A5 PROGRESSIVE 16T

133 Comb Plate G0A453A6 PROGRESSIVE 17T

134 Comb Plate G0A453A9 PROGRESSIVE 15T

135 Comb Plate G0A453AG1 TRAVOLATOR

136 Comb Plate G0A453AG10 TRAVOLATOR

137 Comb Plate G0A453AG11 TRAVOLATOR

138 Comb Plate G0A453AG12 TRAVOLATOR

139 Comb Plate G0A453AG4 TRAVOLATOR

140 Comb Plate G0A453AG9 TRAVOLATOR

141 COMB SECURITY TEST TOOL GAA27DY1 TRAVOLATOR

142 Comb Plate GAA453BM1 24T L=203,184

143 Comb Plate GAA453BM10 23T ALU+PVC L=197,995

144 Comb Plate GAA453BM11 23T ALU+PVC L=197,994

145 23 TEETH ALU+PVC COMB L=206,39 FOR INSERT GAA453BM12

146 24 TEETH ALU+PVC COMB L=203,185 GAA453BM13

147 24 TEETH ALU+PVC COMB L=206,40 GAA453BM14

148 23 TEETH ALU+PVC COMB L=197.994 GAA453BM15

149 23 TEETH ALU+PVC COMB L=197.994 GAA453BM16

150 COMB 194,718MM GAA453BM2

151 24 TEETH ALU COMB L=206,39 FOR INSERT GAA453BM3

152 24 TEETH ALU COMB L=206,39 GAA453BM5

153 23 TEETH ALU COMB L=197,994 GAA453BM6

154 23 TEETH ALU COMB L=197,994 FOR INSERT GAA453BM7

155 24 TEETH ALU + PVC COMB L=203,184 GAA453BM8

156 24 TEETH ALU + PVC COMB L=206,39 GAA453BM9

157 24 TEETH COMB 203,184MM GAA453BV1

158 24 TEETH COMB 203,184MM GAA453BV41

159 24 TEETH COMB 206,391MM GAA453BV5

160 24 TEETH COMB 203,184MM GAA453BV51

161 24 TEETH COMB 206,391MM GAA453BV55

162 23 TEETH COMB 197,994MM GAA453BV56

163 23 TEETH COMB 197,994MM GAA453BV6

164 23 TEETH COMB 197,994MM (FOR DEMARC.INSERT) GAA453BV7

165 COMB FOR NEXTSTEP ESCALATOR (CENTER) GAA453CH1

166 COMB FOR NEXTSTEP ESCALATOR LH GAA453CV1

167 COMB FOR NEXTSTEP ESCALATOR RH GAA453CV2

168 COMB ESC.506 LG=126,945 HD2115-3

169 Comb Plate XAA453AV2 Mid/200*145*145*22T

170 Comb Plate XAA453AV3 Lefr/203*145*145*22T

171 Comb Plate XAA453AV1 Right/203*145*145*22T

172 Comb Plate GAA453BM3 Left/506

173 Comb Plate GAA453BM7 Right/506

174 Comb Plate FX453Y 127/136.5/142.8/145.8/152.3mm

175 Comb Plate A GOA453AG 127mm

176 Comb Plate B GOA454AG 146mm

177 Comb Plate C GOA455AG 152mm

178 Comb Plate GAA453BM1 CENTER/506NCE,510

179 Comb Plate GAA453BM5 LEFT/506NCE

180 Comb Plate GAA453BM6 RIGHT/506NCE

181 Comb Plate LDTJ-B-1 Plastic, Yellow

182 Comb Plate LDTJ-B-2 Plastic, Yellow

183 Comb Plate LDTJ-B-3 Plastic, Yellow

184 HANDRAIL DRIVING CHAIN GO322P100 125Pitches L=3175mm

185 506NCE HANDRAIL SUPPORT CHAIN 8 ROLLERS

186 506NCE HANDRAIL SUPPORT CHAIN 7 ROLLERS

187 506NCE HANDRAIL SUPPORT CHAIN 10 ROLLERS

188 BRAKE TAA20222BE2

189 506 STEP FAA26140A6

190 RUBBER HANDRAIL OTIS TYPE d:38+1.6 D:64±0.5 D1:82+1.5 H:35.5±1

191 DCSS4 GFA24350AW1

192 OPERATION PANEL GAA26220BD2

193 OPERATION PANEL GAA26220BD3

194 OPERATION PANEL GAA26220BD4

195 OPERATION PANEL GAA26220BD5

196 606NCT FRACTION WHEEL GAA265AT1 700MM

197 606NCT SUPPORT CHAIN GAA332Z3 10 ROLLERS

198 606NCT V-BELT POV71AAA1 L=3734MM

199 LIMITED SIWTH TAA177AH1

200 LIMITED SIWTH TAA177AH2

201 PIN ROLLER GO456AY1

202 INLET COVER GAB384NY

203 Door Controller FAA24350BK1

204 70AMPS with VA1+XU1board

205 70AMPS without VA1+XU1board

206 18ATF machine

207 AT120 DOOR CONTROLLER FAA23450BK1

208 BA610AAW1

209 ABA26800GW4

210 DOOR SKATE TECHNA

211 DOOR HANGER ROLLER 85*20-6204

212 ADA26800MB1

213 GAA26800AL1

214 GAA26800AL2

215 GAA26800AL3

216 ACA21290BA4

217 GAA25005 F1

218 GAA657 A4

219 GAA657A1(EMF4)

220 GAA2500F1

221 GAA234AJ1

222 GAA234AJ2

223 GAA234AJ4

224 GAA234AJ5

225 DOOR WIRE ROPE 4MM

226 BRAKE GO222P1 GAA20401F550 GAA20401C501

227 ROLLER FAA456X1

228 PDBII GAA26800KP1

229 Key switch for start-up ASW0335 IND CONT 858T

230 Interlock switch GAA177FW1

231 Interlock switch XCX N 2108P20C

232 Interlock switch GAA177FD2

233 Roller for step GO2215A2

234 Fuse 4A GAA375BY4

235 Fuse 1,6 GAA375AF

236 Roller for Rubber Handrail

237 Ski GO385EP1

238 Plastic cover for front skirt GAA384JY1

239 Plastic cover for front skirt GAA384JY3

240 Plastic cover for front skirt GAA384JY4

241 Plastic cover for front skirt GAA384JY5

242 OVF 30 drive (90 Amp.) ACA21290BJ2

243 OVF 30 drive (120 Amp.) ACA21290BA4

244 OVF 30 drive (120 Amp.) ACA21290BA2

245 OVF 20 CR GAA21343C1

246 TCBC GDA26800KA2 GI

247 INVERTER PCB AFA26800UD2 CONTROL TYPE OTIS 3000B.RECTRFIER TYPE ACA21290 BA4

EXPORT 325volt AC MIN 528volt AC MAX ’48-128 Ampere 50-60Hz 3phaseWiring AAA21290AY1

248 DEMARCATION LL28034032 Yellow

249 DEMARCATION LL8034023 Black

250 DISPLAY NAA20320AAA00

251 DOOR ENCODER AAA633Z21

252 DOOR ENCODER GCA633A1

253 ENCODER DAA633A1 TAA633A1

254 PCB ANSI SPEED CHECK ASCB AAA26800GG1

255 OTIS XIZI LMCS-MCB CB-II GEA21270A1

256 landing Indicator FDA23600V1

257 SERVICE TOOL GAA2175051

258 HANDRAIL DRIVING CHAIN 16B-2

259 MAIN DRIVING CHAIN 20A2

260 Poly-V belt 6J965 FAA717A1

261 Pulley for toothed belt DO2000 FBA198H1

262 Toothed belt door drive DO2000 FAA717B1 L=4400mm

263 contact “father” shunt FO156CK3

264 Contact “mother” FAA156AX1

265 Air cord OP900 FAA712X21

266 Kit of door pulley FAA198V1

267 Kit of door pulley FAA76D3

268 160VAT TRACTION WHEEL 575*5*10mm

269 SOM-A9693F

270 SOM BOARD A9693F

271 FAA177AJ1

272 AAA21305Q1

273 step XJ1200\1000\800XZ-A

274 XIZI STAINLESS STEEL DEMARCATION L48034049A

275 XIZI STAINLESS STEEL DEMARCATION L48034047A

276 XIZI STAINLESS STEEL DEMARCATION L48034047B

277 XIZI STAINLESS STEEL STEP XAA26340H3

278 apply the brake 160 VAT T0C5048b1 instead homegrown

279 CODER AAA633Z1

280 escalator driving VELT GCA717D1 Homegrown

281 LCD show FAA25100K1

282 Door roller GAA456AY1

283 GAA265NNN1

284 show JAA25140AAD102

285 GEA23550DIC product from Germany

286 constantan wire resistance

287 STAINLESS STEEL BUTTON AAA23500AM1

288 Inverter GAA225JK1

289 GUIDE RAIL GAA27078K36

290 GUIDE RAIL GAA27078K4

291 GAA177HR1 original only have 1~2 piece

292 OTIS Pacific chain(to copy Toshiba) 66.66 every node

293 escalator sensor DAA177AX2

294 Bottom guide balustrade Otis 506NCE GAA27078K83

295 GAA27078K72

296 GAA27078K78

297 braking vane EG-SW G2D90FC DAA610F1

298 Backspace guide rail GCA402BP1

299 STEP GAA26140

300 DAA25140NNN6/13

301 DAA25005A2

302 RSEB DAA26800J1 NEW

303 76.2 x 22 mm GA290AJ11

304 TCBC GDA 26800 K 10

305 MCB 3 GCA 26800 KF 10

306 DCSS 5 black box GJA 24350 BD 11 secondhand

307 PDB GDA 26800 J10

308 MCB ll GDA 26800 H10

309 button glow FAA 25090 K121

310 button glow FAA 25090 AD111

311 DRIVE CONTROL BOARD GCA 26800 AH50/5KW

312 EPRON G0161G44 FOR MCS 310-Z29

313 EPRON GOC 616G49 FOR MCS 312-Z29

314 EPRON GOD 616G34 FOR MCS 310-Z30

315 EPRON G0616G50 FOR MCS 312-Z30

316 coder FAA 633B1 FOR DO 2000

317 B module SKD 62/16

318 B module SKD 82/16

319 Transistor QM 150DY-2H

320 Transistor MG 150Q2YS40

321 Transistor MG 75Q2YS40

322 Transistor MG 150 YS40

323 Transistor MG50Q6ES40

324 DOOR CONTACT AZ14-1 KDL

325 DCSS5 GJA24350BD11 STEEL BOX

326 SHOW PCB GBA250005D1 OTISJF0003

327 Control PCB CPM2B-60CDR-DCH-CPU XIZI OTIS escalator parts

328 SWITCH LX2-412 (ZR231) LX2-412 (ZR231) XIZI OTIS escalator parts

329 DEMARCATION XAA455N1 1200R XAA455N1 XIZI OTIS escalator parts

330 DEMARCATION XAA455K1 1200 XAA455K1 XIZI OTIS escalator parts

331 DEMARCATION CN023435364 BLACK L47332092A 1000 L47332092A XIZI OTIS escalator parts

332 DEMARCATION L47332091A YELLOW 1000 L47332091A XIZI OTIS escalator parts

333 DEMARCATION XAA455Q left XAA455Q XIZI OTIS escalator parts

334 DEMARCATION XAA455R1 right XAA455R1 XIZI OTIS escalator parts

335 13VTR MACHINE the same to the spain140VAT

336 BOARD A9693D2

337 COMB PLATE XXA453BJ middle193.2*145*143 Side 214*145*142 23 tooth, in side 25tooth used in 1m step middle 23tooth it side 24tooth is used 800 step

338 3200 Controller Board RCBII GEA21270A1+LMCSS-MCB GFA26801AAF002 +OVF30-70AMPS OR OVF30-90AMPS OR OVF30-120AMPS +SOMII GAA26800AL1 OR SOMII GAA26800AL2

339 AT120 DOOR BLET CLIPS 25F-FAA23050G

340 XIZI OTSI step 53-XAA26140 the same with the GAA26140

341 OTIS step roller XAA290CY1 skeleton 76*22-6203

342 OTIS 506NEC HANDRAIL DRIVE CHAIN 16B-2

343 OTIS 506 HANDRAIL DRIVE CHAIN 16B-2 125 bitch

344 OTIS 506 HANDRAIL DRIVE CHAIN 16B live bitch

345 OTIS 506 MAIN DRIVE CHAIN 20A-2 96 bitch

346 OTIS 506 MAIN DRIVE CHAIN 20A live bitch

347 OTIS 506NEC step 1000mm silver

348 HANDRAIL GUIDE STRIP GAA50AHA1 L=6000mm

349 OTIS 506 over speed sensor

350 to drive DAA494NPA2

351 LMCSS JGA26801AAF105

352 PDB (Power Drive Board) 9kw GDA26800J10

353 PDB (Power Drive Board) 15kw GDA26800J50

354 PDB (Power Drive Board) 5kw GDA26800J20

355 ENCODER for OVF20 JAA00633ABF003 JAPANESE TYPE REPLACE

356 ENCODER for OVF30 TAA633A1 JAPANESE TYPE REPLACE

357 RS11 GBA25005A1

358 RS 14 (Remote Station 14) GDA25005B10

359 RS 18 GDA25005C20

360 LWDE FBA24270AA1

361 CPI 10 (Car Position Indicator) FAA25100J1

362 PUSH BUTTON (green) FAA25090A112 A312 button

363 DOB FAA25090J114 need photo

364 NUT FAA72N1

365 SOM Board GEA26800AL10

366 SERVICE TOOL GBA21750S1

367 Hall Button Box FAA147CH23

368 Hall Button Box FAA147CH33

369 Hall Button Box FAA147CH63

370 SPBC III GBA26800KX1

371 SPB-ANS GAA26800KS1

372 Transformer GAA225LL1

373 Transformer GAA225MR1

374 Interface Board (LVIB) 22kw ABA26800XU2

375 Interface Board (LVIB) 32kw ABA26800XU5

376 HBB GBA25005D10

377 Door Interface Subsystem C9693MB1

378 Alternate Door Interface Subsystem B9693MG2

379 DBR (Drive & Brake Resistor) GBA21295H2

380 CPI 11 (ELD Display) FAA25250C1

381 Inverter (DBSS) 32 KW,210 A ACA21290BM1

382 INVERTER BOARD ACA26800UD2

383 DCSS 5 GJA24350BD11

384 DCSS 4 GDA24350AW11 second hand 5000

385 Porter Intercom Unit FAA512AC8 FAA512V1

386 GDB GBA26800KC1 need photo

387 Processor Board ADA26800VA1

388 Battery Charger FAA628H1

389 24V KEY SWITCH FAA431E14

390 Door Encoder FAA633B1 need photo

391 friction pulley GAA265AH 781

392 Chain GO332P12

393 Chain GO332P13

394 ABA26800AKT1

395 Inverter -SIEI 7.5KW (with the gear) XAA622R18CH

396 Inverter-SIEI 11KW (with the gear) XAA622R19CH

397 Inverter-SIEI 15KW (with the gear) XAA622R20CH

398 Inverter-SIEI 18.5 (with the gear) XAA622R21CH

399 Inverter-SIEI 22KW (with the gear) XAA622R22CH

400 SIEI30KW Inverter (with the gear) XAA622R23

401 AGY11KW Inverter(escalator) XAA622Q1

402 15KW Inverter AGY3150(escalator) XAA622Q2

403 Inverter OVF20-9KW GCA21150C10

404 Inverter OVF20-15KW GCA21150D10

405 GEN2 Inverter GAA21382H1

406 GEN2 Inverter 1600KG Upon GAA21340P10

407 GW4 ABA26800GW4

408 XU1 ABA26800XU1

409 VF1 ADA26800VF1

410 VA1 ACA26800VA1

411 BA2 ACA26800BA20

412 BG1 GAA26800BG1

413 DISS JAA26805AAA201

414 ADISS (home-made) B9693MG1

415 MCB(MCSS) JGA26801AAF002

416 MCB-II GCA26800H10

417 RCB-I A9693D

418 LDB board JAA26807BAR001

419 MCB3 GCA26800KF20

420 TCBC GCA26800KA10

421 RCP JAC26801AAJ004

422 ABL001 ABA26800ABL001

423 LWB (weighing device) GAA24270AB2

424 LTB(GEN2) FAA25000E1

425 LB2(The housing ladder) GBA21230F10

426 SPBB1(GEN2) GCA26800BB1

427 BB2(GEN2) GCA26800BB2″(GBA)

428 LEM ABA26800SY1

429 RCB-II GGA21270A1

430 SOM (homegrown) XAA610AH1

431 RS-5J(import) GFA23550D1

432 ACBII (homegrown LCBII) XAA610AM1

433 SPB XAA610AC1

434 RSEB (homegrown) XAA610P1

435 LPB2 XAA610K3

436 RS-5(homegrown PCB) XAA23550A1

437 RS-5 XAA610AK1

438 AMCBI board (signal interface board) XAA610Q1

439 AMCBII board (signal interface board) XAA610W1

440 HCB board (OH1000 using) XAA610S1

441 XRDS (portal crane board) XAA24350J1

442 UX2 AAA26800UX2

443 RS13(domestic) DAA23550NNP1

444 Interfere with the absorption board(import) JBA26801AAX

445 Interfere with the absorption board(import) JBA26801AAN

446 RS-11 GCA610XA1

447 Homegrown RSAB-4

448 9693 BOARD XAA642A1

449 TO-30-LB D9673T-3

450 TO-30-IB GOA9673GP1

451 TO-30-EB-3 A9673W

452 TO-30-MLB A9673AF

453 TO-40-NPWL-LA03 N62P10005

454 TO-40-CIB GOB 9687 D1

455 TO-40-SGB JO 6840FR 3

456 TO-40-MP3 LB JO 6840RH 8

457 TO-40-MP3 LB JOA 6840RH

458 TO-40-CUBI JOA 6840FT 1

459 TO-40-TTB JOA 6840FP 1

460 TO-40-TTB JOAB 6840FP

461 TO-40-CUB2 JOE 6840FV 2

462 TO-40-CUB2 JOC 6840FV

463 TO-40-IIB JOC 6840RH 8

464 TO-40-IIB JOC 6840FS 1

465 TO-40-MIB DO 6840F 1

466 TO-40-MIB JOA 6840GC 1

467 TO-40-BAKB JOA 6840GD 1

468 TO-40-JO 610GJ N62P20105 (with 5 pieces Long capacitance)

469 TO-40-JO 6840GK N62P20104 (with 4pieces transformers)

470 TCBCZ31 CHIP GAA30084BAB031

471 LCBII CHIP GAA30083AAD1

472 ELAR-1 XAA20351C001

473 OMS (ES-SW BOARD) XAA610E1

474 Inverter Frequency division card-SIEI (APC100-1) XAA616AL2

475 Inverter expansion cards-SIEI (EXP-D16card) XAA616AL4

476 Inverter expansion cards-SIEI (EXP-E-TL card) XAA616AL8

477 Inverter expansion cards (EXP-DBSS card) XAA616BN1

478 card DO-08 XAA610AB2

479 card DI-08 XAA610AB1

480 card PG-B2 XAA616AJ1

481 Escalator microcomputer board (CPM2B) XAA616Z1

482 Reset layer safety circuit board (5000.5100) XAA610AT1

483 GEN2 coder ABA633Z21

484 GEN2 coder ABA633Z1

485 A311 coder ABA633L1

486 gearless coder (1387style) XAA633AA1

487 A411 coder A633D1

488 A411 coder AAA659C3

489 coder DO2000 (Home made) XAA633AC1

490 EC2-7main encoder GAA20401T621

491 coder (Italian speed measuring machine) XAA20500A1

492 Alloy speed measuring joint XAA648D1

493 Plastic speed measuring joint ABA215BX2

494 Light bulb 24V1W XAA417K1

495 photoelectricityE4(E3S-GS3E4) XAA177AZ2

496 photoelectricityB4 XAA177AZ1

497 escalator photo electricity XAA177AZ5

498 photo electricity sensor XAA608E1

499 photo electricity (SSGD1-L normal closed) XAA177DB1

500 photo electricity CEDES XAA177AZ3.AZ4

501 photoelectricityCRD-300N(escalator) XAA608E2

502 LAMDA3 optical screen line AAA174VZ1

503 CEDES optical screen line XAA175BL1

504 optical screen LAMBDAIII (OTIS) ABA24591T8

505 optical sensor E3JK-5M2 XBA24590G2

506 secondary contact SZ-A20 XAA156K1

507 secondary contact SZ-A22 XAA156K2

508 contact SC-N2AC110V XAA638S1

509 contact SC-N3AC110V XAA638B1

510 contact SC-4NAC110V XAA638S2

511 contact SC-5N XAA638S6

512 Fuji SC-N4 contact AC110V-80A

513 Fuji SC-N3 contact AC110V-65A

514 Fuji SC-N2 contact AC110V-35A

515 Fuji SH—4/G contact AC220V-2K2B

516 Fuji SH—4 contact AC110V-2K2B

517 Fuji SH—4 contact AC110V-3K1B

518 Fuji SH—4 contact AC110V-4K

519 Fuji SH—4 contact DC24V-2K2B

520 Fuji SH—4 contact DC110V-2K2B

521 Fuji SC-4-1 contact AC110V

522 SC-03 relay AC110V3 open 1 closed

523 SC-03 relay AC220V3 open 1colsed

524 LG relay DC24V (2open 2 closed)

525 LG relay AC110V (3 open)

526 LG relay AC220V (3 open)

527 Lgrelay AC220V (2 open 2closed)

528 220V electric power JZC1 (3TH82 4open 4colsed

529 DC24V electric power DC-DC POWER

530 relay LY2DC110V XAA613Q1

531 relay MY4Z24VDC japana XAA613S5

532 relay SH-4AC110V series XAA613B1

533 relay SH-4DC110V series 231 XAA613A1

534 break relay SC-03AC110V XAA613AB1

535 relay SC-4-1 XAA638S4

536 relay Base MY4 XAA618H2

537 relay Base LY4 XAA618G1

538 relay Base MM4XP XAA618D1

539 time relayBaseH3CR XAA618AV1

540 auxiliary contact AU-2 (1open 1closed) XAA156F1

541 auxiliary contact AU-2 (2open 2closed) XAA156F1

542 AU-4 contact XAA156J1

543 assit contactAU-1 XAA156P1

544 Power switch Z-15G-B XAA177BV1

545 Power switchZ-15GQ22-B XAA177BV2

546 Power switchZ-15GWZ-B XAA177CP1

547 Lithium battery 200HBAT09 XAA621M1

548 Lithium battery 3G2A9 XAA621N1

549 CEDES control box XAA24350AF1

550 LAMDA3 control box ACA24591R1

551 LCD SHOW 5.4 vill XAA25140G1

552 LCD SHOW 5.4vill decoding deck XAA610H1

553 transformerAT25 XAA225AJ1

554 Bottom pit repair box GEN2 DAA7004D1

555 Bottom pit stop switch box GEN2 DAA175D1

556 Emergency power supply and alarm box GEN2using DAA718A1

557 Additional power box GEN2 using DAA621E1

558 VG5 fan XAA301H1

559 11-15KW transducer fan MMF06024DS

560 22KW transducer fan5915PC22TB

561 time relay H3RDC24V without base XAA613P3

562 time relay H3CRAC110V with base XAA613AA1

563 GEN2 roller guide shoe (No three Angle board) XAA24180A1

564 GEN2 roller guide shoe (with three Angle board) XAA24180A2

565 roller guide shoe XAA456K1

566 Ultra high pressure protection switch XAA177CT1

567 filter screen XAA737B1

568 Old type feedback head (hydraulic ladder backs pan) XAA20311B001

569 Emergency drop valve XAA20301B001

570 The upside valve core XAA20301A008

571 Down valve assembly XAA20301C003

572 hydro cylinder objurgating ring BZG-100 XAA20381A018

573 hydro cylinder objurgating ringBZG-110 XAA20381A019

574 hydro cylinder objurgating ringBZG-120 XAA20381A020

575 hydro cylinder objurgating ringBZG-125 XAA20381A021

576 OTIS2000 door vane FEA24390C1

577 step lost sensor XAA177DH1

578 main roller (506step) GXF0290AR502

579 Screen copy shows ELD car ADB23750AAA004

580 Screen copy shows ELD Outside the hall ADB23570AAA001

581 ELD power AAA24591K1

582 double 8 Outside single staircase hall display (import) JAA25140AAD122

583 single 8And outside the staircase hall display (import) JAA25140AAF102

584 dual 8And outside the staircase hall display (import) JAA25140AAF122

585 single 8 Control box core (import) JAA25140AAB003

586 dual 8 Control box core (import) JAA25140AAB103

587 LANTER Landing Direction Indicator (import) AAA23500M4

588 The motor housings140VAT XAA384FN1

589 The motor housings13VTR DAA346AJ1

590 The motor housings16VAT TAA384CJ2

591 16VECDisc wheels XAA353A1

592 13VTRDisc wheels TAA290B1

593 13VTRaluminium alloy Disc wheels T0290BV1

594 13VTR trig loop 11KW DAA330E2

595 160VAT trig loop 160VAT TAA330BA1

596 18ATF trig loop TAB330AJ1

597 Brake shoe 10*100 (10*140) XHW151B1

598 Brake shoe 13VTR. 16VAT (TAB416P2) TAA416P2

599 Brake shoe 140VAT TAB416P2

600 Brake shoe 18ATF TAB486G1

601 17CT Brake shoe JY416AT2

602 hoisting cable (japana import12.7) XAA712E14

603 The composite steel belt (GEN2)1350KG using AAA717W1

604 The composite steel belt (GEN2)1350KGusing AAA717R1

605 speed limited (import) TAA20602B41

606 speed limited (used GEN2) TA20602A361

607 safety tong (used GEN2) A9672D201

608 safety tong (import) A9672E19

609 Buffer (used GEN2) FAA320BB1

610 Buffer GEN2-R2-1600KG/1. 75M/S FAA320R4

611 17CT traction machine JO260AD45

612 traction machine 18ATF TAB260B16

613 ECH3 trig loop (021) XAA20236B2

614 ECH3 trig loop (020) XAA20236B1

615 ES-SW main brake loop CSA00C021A

616 escalator sensor GO177BH

617 16VEC near the power switch

618 18ATF take off the brake wrench TAA286AJ1

619 140VAT take off the brake wrench JAA20136AAB001

620 0H5000 wrench

621 Handrails before population protection board (Emigration) GAA346PL1

622 TAA215F3 Coupling elastomer TAA215F3*TM

623 17CTHost families cover

624 12VEmergency flat device battery

625 serial interface board using for control cabinet (XAA610AE1)

626 serial interface board using for maneuvering box (FO) XAA610AE2

627 Absorb the unit SZ/Z5 XAA276C3

628 elastomeric EC-SW

629 elastomeric EC2-7

630 oleo-electrical synthetic glass XAA386BNL1

631 5Core light eyeliner XAA175AW1

632 2Core light eyeliner XAA175AW2

633 MG5AC110V relay (from tianjing) XAA638AK1

634 Button XAA323AK1

635 ButtonBR27 (Home made) XAA323S1C

636 ButtonBR23 XAA323G4

637 ButtonBR34A XAA323N1

638 ButtonBR34 (First letter) $X/XAA323N1

639 BS34 button (First letter) $X/XAA323P1

640 pitch button (OH5100)

641 button BR54 XAT999A40

642 button BS34A XAA323P1

643 A313 button

644 OTIS-40 button

645 stainless steel with the Braille (-1—9)

646 BR34 button character

647 BS34 button character

648 BR27 button number character XAA323BE1A

649 import BR36 button (hair line stainless steel) XAA323Q1

650 import BR36 button (mirror faces taintless steel) XAA323Q2

651 import BR36 button (titanium) XAA323Q3

652 import BR27 button (mirror face stainless steel) XAA323L2

653 BR27hair line stainless steel button XAA323L1

654 BR27Without the bottom box button XAA323BQ1

655 England key-stroke XAA323AA1

656 BR27 Press the elliptical character sheet (hair line) XAA323D1/D2

657 keypad (mirror face With Braille) XAA323D2

658 GEN2 The base station lock FAA431B1

659 Operate box hook lock (passenger-goods lift) XAA431J1 XAA431AA2

660 electric door lock 21VF XAA431H1

661 electric door lock (DS-4) XAA431Z1

662 power switch (six pin) XAA177T1

663 power switch LX29 XAA177AP1

664 power switch PB78 XAA177CB1

665 power switch UKS XAA177BH1

666 power switch UKT XAA177BL5

667 door lock over travel-limit switch X2-11 XAA177AP2

668 fireman switch (single. ordinary) XAT999A22

669 Bitable magnetic switch KCB XAA177AS1 (XAA661G1)

670 limited power switch EL-1375 XAA177DA1

671 EL1376 power switch XAA177EC1

672 safety tongs switch XAA177BL1 (TAA177AH)

673 screen show ELD (6.4inch XAA25140E3

674 screen show ELD (8.4inch inside car) XAA25140AC1

675 screen show ELD (8.4inchOutside the hall) XAA25140AC2

676 single 8 Control box core21VF XAA25140AAB201

677 dual 8 Control box core21VF XAA25140AAB202

678 single 8group control Outside the hallINTER-MACHINE21VF XAA25140AAF002

679 single 8horizontal typedisplayINTER-MACHINE21VF XAA25140AAA002

680 dual8singlestairOutside the halldisplayINTER-MACHINE21VF XAA25140AAD022

681 dual8group control Outside the halldisplayINTER-MACHINE21VF XAA25140AAF022

682 dual8horizontal typedisplayINTER-MACHINE21VF XAA25140AAA022

683 411cardisplay

684 XO/dual8 parallel connection Codified board (two-in-one) XAA23550A5

685 XO/single8 Codified board Chinese (two-in-one) XAA23550A2

686 XO/dual8 Codified board Chinese (three in one) XAA23550B4

687 dual8 Codified board Chinese (two-in-one) new type

688 XO/single8 Codified board English (dual tier) JAA25140AAC102 (upgrade type)

689 XO/single8 board Chinese (dual tier) JAA25140AAD106

690 XO/dual8Codifiedboardchinese (dual tier) XAA25140AAD022

691 XO/dual8parallel connection Codified board English (dual tier) JAA25140AAD126

692 XO/dual8parallel connection Codified board English (dual tier) XAA25140AAF122

693 XO/dual8Codifiedboardchinese (two-in-one) XAA23550A3

694 XO/single8parallel connection Codified board Chinese (two-in-one) XAA23550A4

695 XO/single8Codifiedboardchinese (three in one) XAA23550B3

696 No bottom box dual eight display

697 No bottom box single eight display

698 2 in 1 display displayXAA23550A2

699 single8dual8group control display board (three in one) XAA23550B1.B2

700 single8maneuvering box display (three in one) XAA25140AB1

701 dual8maneuvering box display (three in one) XAA25140AB2

702 singlestairsingle8display XAA25140V1

703 singlestairdual8display XAA25140V2

704 car display – dual8 XAA25140K1

705 Outside the hall display – dual8 XAA25140L1

706 XAA23500D9

707 XVFsingle8Codifiedboardchinese (three in one)

708 dual8Codifiedboardchinese (three in one) DAA25140NNN6

709 dual8Codifiedboardchinese (three in one) DAA25140NNN14

710 dual8Codifiedboardchinese (three in one) DAA25140NN6

711 dual8Codifiedboard (three in one) DAA25140NNP10 (English)

712 dual8parallel connection Codified board Chinese (three in one) DAA25140NNN2

713 dual8parallel connection Codified board (three in one) DAA25140NNP14 (Chinese)

714 single8parallel connection Codified board Chinese (three in one) XAA23550B1

715 single8Codifiedboardchinese (three in one) KEY

716 emergency supply DC-12V XAA621J1

717 permanent magnet relay XAA613AN1

718 interphone 934B XAA25301G1

719 one to others Intercom channel5050HZ XAA25304B2

720 interphonemainframe1 by 1mainframe202 XAA25302A3

721 HDZ-30011by 1mainframe XAA25303A1

722 1 by 1mainframeHDZ-4001 XAA25305A1

723 The three of intercom GEN2mainframe XAA25301H11

724 GEN2interphone House to pay the machine XAA25301H2

725 1by 5mainframeHDZ-4005(5set) XAA25305A2

726 HDZ-200D2 electric power XAA25302C1

727 HDZ-200D3 electric power XAA25302C3

728 HDZ-200D4 XAA25302C2

729 five orientations talkback power strip XAA25302G1

730 1to 5machine tools XAA25302A2

731 1to public machine toolsHDZ-980A XAA25304A1

732 HDZ-980 public machine tools XAA25304A3

733 five orientations talkback mainframe XAA25302A6

734 talkback donkey engine talkbackHDZ-3001F XAA25303B1

735 talkback donkey engine talkbackHDZ-300FA XAA25303B2

736 talkback donkey engine talkbackHDZ4001F XAA25305B1

737 talkback donkey engine talkbackHDZ-201FA XAA25302B3

738 talkback donkey engine talkback XAA25302B5

739 five orientations talkback XAA25302B6

740 GEN2talkbackdonkey engine talkback donkey engine talkback XAA25301H10

741 Its top car bottom talkback donkey engine talkback XAA25305B5

742 4001 type talkback donkey engine talkback XAA25305B4

743 talkback power XAA25302F1

744 single phase power Filters HL-06D

745 rectifier bridge AC31V=DC28V

746 transformer 220=DC105V

747 transformer (XAA225BF6) 400=DC28/10A.AC24/9A.AC110/5A.AC220

748 transformer (XAA225AS1/AS2) 400=DC28/10A.AC24/9A.AC110/5A

749 transformer (XAA225BA1) 400=DC110.AC24.AC110

750 transformer (XAA225AQ1) 400=DC28/10A.AC24/15A.AC110/5A

751 transformer (XAA225AC1) 400=DC110.AC24*2

752 transformer (TDB-800-06) 380=AC122.AC72

753 transformer (TDB-1020-01) 400=DC165*2

754 transformer (XAA225AM2) 400=DC110.2,5A/AC110V/AC24V

755 transformer (goods elevator TDE-142) XAA225P4

756 transformer TDE-101(36V) XAA225P1

757 transformer TDE-102 XAA225P2

758 transformer TDE-521 XAA225R1

759 transformer XAA225AS1

760 transformer 5100 XAA225AS2

761 transformer ACVV380/220 XAA225AG3

762 transformer XAA225AM2

763 call box double/and with fire-control/middle/BR34A XAA23500FD10-A (hair line)

764 call box double/and/with fire-control/below/BR34A XAA23500FC11-A (hair line

765 call box single /and/without fire-control/middle/BS34A XAA23500EK2-A

766 call box double/and/no/The basalBR34A XAA23500EH10-A

767 call box double/single/no/stratum basale BR34A XAA23500ED10-A

768 call box single/single/no/In the basetierBR34A XAA23500EE1-A

769 call box double/single without/middle/BS34A XAA23500EA11-A

770 call box single/single/toplevelBR34A XAA23500EB1-A

771 call box single/single/mesosphere/BR34A XAA23500EA1-A

772 call box BS34Asingle8 show middle (Plastic bottom box) XAA23500EA11A439

773 call box BR34Adual8 show middle (Plastic bottom box) XAA23500EA10A439

774 call box (house stair top tiersinglebuttonBR23) XAA23500AE3

775 call box (house stair middle tierdualbuttonBR23) XAA23500AE5

776 call box(XHW middle) XAA23500GC9

777 HPBcall box XAA23500R2

778 HPBcall box XAA23500S2

779 HPBcall box XAA23500X2

780 call box(horizontal typedisplaydual8) XAA23500D5

781 maneuvering box cranberry glass XAT999A34

782 escalator synthetic glass

783 fire-fighting synthetic glass XAA147AQ1

784 IC card XAA616AL1

785 card-reader-Outside the hallRFC08 XAA616AK2

786 card-reader-Outside the hallRFC07 XAA616AK3

787 read-punch read in machine XAA616BG1

788 car top inductor (GEN2) GAA177BH5

789 rope hand (to weith system) XAA386AXT

790 to weith system ZCW-2000+ XAA24274B1

791 to weith system DZKDD-1X-W35 XAA24275B1

792 passing chime21VF XAA311G1

793 passing chimeXVF XAA311H1

794 E311Outside the hall passing chime bottom state XAA269F3

795 electric bell 220V XAA311F1

796 electric bell DC12V XAA311F2

797 pit power switch1A XBA177BN2

798 pit power switch1B XAA177BN6

799 annex power pack. XAA308GV1

800 car top check box STAR.OH5000.FOVF XBA24830D1(XAA24831A4)

801 car top check box21VF XBA24830D2

802 car top check boxMCS220M XBA24830D3

803 car top check boxMCS321 XBA24830D4

804 car top check box HOME-LIFT XBA24830D5

805 car top check box XHW XBA24830G1

806 car top check box LCBII hydraulic pressure XBA24830G2

807 car top check box FO goods elevator XBA24830G3

808 copper core1.13 XAA175R2

809 copper core10 square XAA175AC1

810 screening wire RVVP9*0.12 XAA175N4

811 6core screening wire XAA174K7

812 round cable 7core XAA174Y1

813 cable 9 core multiple twin XAA174Z1

814 cable 32 core(with the screen) XAA174AB4

815 cable 39 core XAA174Y8

816 surname cable 36core (without the piug-in) XAA174D2

817 retinue cable 22*0.75+2*0.25 (GEN2) FAA25500S999

818 electron arc suppressor XAA605A1

819 140W22 ohm age XAA617B10

820 140W320 ohm age XAA617B11

821 pressure-sensitive resistance XAA617D1

822 1KW80 Ohm resistance box XAA21305A4

823 trig resistance box 1500W100 ohm (2 pieces parallel connection) XAA21305A5

824 trig resistance box1500W20ohm (4pieces parallel connection) XAA21305C1

825 trig resistance box1200W28ohm XAA21305C7

826 trig resistance box2000W11.6ohm XAA21305D1

827 trig resistance1500W3ohm XAA232Y2

828 trig resistance1000W100ohm XAA232W2

829 resistance piece 1.95 ohm XAA232D1

830 resistance piece 2.80 ohm XAA232AV2

831 4hole oblate plug XAA618AB2

832 anti-riot light (Light plane ship) XAA417N1

833 Buzzer 21VF XAA731A1

834 Buzzer24V XAA731C1

835 calculagraph HLTC220V XAA630J1

836 crosscurrent fan (high power) (422A) XAA24720J2

837 crosscurrent fan (lower power) XAA24720J1

838 square fan XAA24720E1

839 air outlet 463×43、open holes 483×93, 40W car fan

840 air outlet 450×43、open holes 473×93, 40W car fan(1042)

841 air outlet 268×43、open holes 383×93, 40W car fan(9B)

842 car fan(goods elevator)

843 transform power switch (car top) XAA323AC2

844 three open one closed transform power switch XAA323AF6

845 control box read small button XAA323K1

846 car door power switch XAA177BC1. BD1

847 hot protector XAA613AR1

848 phase sequence encoder ABJ1-122 XAA613AT2

849 ring-shaped strip lamp XAA417E2

850 rocker die (whole plastic) XAA237F1

851 triangulation chain core around XAA431AB2

852 triangulation key XAA431AB1

853 Unloading rod XAA431AB3

854 guide shoe inside shoe lining XWP243C2 XAA237D

855 shoe guide (Mitsubishi 120*16) XAA380N1

856 shoe guide (mitsubishi120*10) XAA380N2

857 shoe guide 120*17 XAA380G1

858 shoe guide220*17 (XAA256J3) DTJ1501-3

859 GEN2shoe guide (splint) FAA380F500

860 roller guide shoe guide XAA380K1

861 oil cup XAA349C1

862 Guide shoe (Mitsubishi) XAA2416+1B1

863 Guide shoe (with the metallic reed) XAA24161A1

864 hydraulic pressure elevator roller guide shoe XAA24186A1

865 GEN2 car guide shoe XAA237J1

866 guide shoe 1.75M/S XAA237D2

867 passive door lock XAA177CR1

868 door lock 10.4around XAA431Y1

869 PB-D16 door lock

870 door lock161 XAA431R1

871 sundries elevator door lock XAA431G1. G2

872 hall door shock leather XAA320AB1

873 shockproof piece (escalator enter) XAA310YE1

874 Heavy steel wire rope M=900MM XAA712X1

875 Blade rubber wheel XAA290DA1

876 roller (Swinging rod hanging round) XAA290BW1

877 roller 203 XAA290BX1

878 621 roller with the axis XAA290BV1

879 eccentric XAA502K1

880 belt 1120 XHW260A1

881 belt1400 XHW260A2

882 1460 triangle belt XAA717H2

883 1420 triangle belt XHW260B1

884 test speed velt XAA717G1

885 fag end assemble 13 XAA20771D131

886 12 fag end assemble XAA20771B121

887 sound insulation sheet rubber XAA310E4

888 plastic rubber sheet XAT995A10

889 copper sheathing 19KW XAA465BT1

890 double XAA24550C26-36

891 safety connect board (Chinese type) XAA24550B1

892 the alum sill 55 W M=800, 900 XAA426F2. F3

893 the alum sill 75 W XAA280A6

894 door vane038 XBA477P1

895 door vaneDO2000 XAA477E3

896 electric motor 123W XAA20500H2

897 electric motor 177W XAA20570L1

898 electric motor XRDS XAA20500H1

899 Expanding system (air stairs) XBA22710B1

900 Expanding system (escalator) XAA26183R1

901 Expanding system GEN2-X XAA22717A2

902 Mention knife block XAA385Y1

903 stainless steel a unit cards XAA102R9

904 titanium single plate XAA102R11

905 stair Disc wheels

906 J1.1mainframeretraint coil

907 J1.1mainframeretraint coil(dual) XAA175BM1

908 OH5000retraint coil

909 OH5000 Brake Base XAA293L12

910 13VTRoil seal 80*55*12 XWQ281C1

911 17C oil tight JAA00033AAB1

912 17C oil tight 73*49*10 (XWQ281D2) JAA00033AAA1

913 240mainframeoil tight XWQ281B1

914 60HT brake shoe

915 blower capacitance ACVV XAA226S1

916 draught fan INTER-MACHINEACVV XAA301J1

917 160VATmainframe draught fan TAA600E2 (XAA301G1)

918 elevator ca air conditioner TK-22Y XAA24720D1

919 cover board special nut GAA72BT1

920 special nut (elevator) XAA72X1

921 4*16stainless steel nut

922 equipment room jiack box 80A (tianjing) XAA177BX3

923 car door pendant 900 (XAA389AP4/10.1000) XAA389AC1

, 924 compen sating chain 1.23KG/M XAA332K12

925 compen sating chain1.47KG/M XAA332K15

926 compen sating chain1.49KG/M XAA332L15

927 compen sating chain1.99KG/M XAA332K20

928 compen sating chain2.23KG/M XAA332L22

929 compen sating chain guide system XAA22801C

930 spring buffer DTJ1702 (1000KG) XAA90AB1

931 spring buffer DTJ1703 (5000KG) XAA320F3

932 spring buffer DTJ1704 (2000KG) XAA320F2

933 spring buffer DTJ1705 step H=305 XAA320F4

934 overrunning governor XAA20601A4

935 overrunning governor XBNA20607A4

936 safety tongs AQ1.0.63-1.75M/S XAA24122A14

937 safety tongs AQ2 XAA24122D1

938 safety tongs QJB2500 (0.63-1.75M/S) XAA24121A4

939 hydraulic pressure buffer 1M/S XAA320E13

940 hydraulic buffer 2M/S XAA320E14

941 polyurethane bufferZDQ-C-6 XAA320F13

942 counterpoise roller DTJ1604A XWP232B1

943 530-4*13 counterpoise roller XAA256N2

944 530-5*13 counterpoise roller XAA266N3

945 520-4*13 counterpoise roller XAA266N4

946 520-3*13 counterpoise roller XAA266N5

947 escalator advancing front board (middle board 1580*470) XAA457BA1

948 directive wheel DTJ0501 XWP230A1

949 directive wheel 560DTJ0504 XWP230B1

950 directive wheel 560- (6*12) DTJ0509 XWP230C1

951 directive wheel parts XAA20751H13

952 car top roller system 560-3-13 XAA24061K2

953 car top roller system 520-4-10 XAA24061K3

954 car top roller system 520-5-10 XAA24061L1

955 car top roller system 560-5-10 XAA24061L2

956 teaction machine 3-13700 (13VTR) TAA260H1

957 teaction machine roller 5-13-610 XAA260E1

958 teaction machine roller J1.1 $X/XAA260F1

959 controller door hinge XAA391E1

960 landing door system (dual pull down type1500) XWP210AG1

961 landing door system (dual pull down type1800) XWP210AN1

962 Chinese dual type landing door system M=2800 XWP210CS1

963 Chinese dual type landing door system M=2600 XWP210CD1

964 Upper can Alyssa stroke 600-1200MM XWP206AA1

965 Beside the hom opened dual type 700-1500MM XWP206AB1

966 hall door upper sill M=900 XWP206B1

967 GEN2The upper sill box OP=900 XWP206L1-2

968 M=800 The upper sill XAA409AL4

969 Stroke double door folding machine (including control panel) XWP211Z1-1(OP=2600)

970 M=1500 Double folding door machine system (including control panel) XWP211G1-1

971 Counterweight rack 520-3*13 XAA25701H15

972 Counterweight rack (without counterweight parts) XAA25705C1

973 Counterweight rack (including counterweight parts) FAA25700CC1

974 without door frame glass car door 900*2100 XAA24770B

975 without door frame glass car door 900*2100 XAB24470B6

976 without door frame glass car door 900*2100 XAA23100B

977 with door frame glass car door M=900*2100 XAB23100A6

978 tour glass (one piece) moisture by 3 pieces $X/XAA24700.0.1

979 paint OTIS XWQ201B4

980 OH5000 encored line

981 yellow hurried Stop retainer XAA137AE1

982 Double 8 And ladder call panel

983 U style filler block

984 25 tooth double chain roller ES2.2.1-1(XAA195X2)

985 29tooth Harvard chain roller PNS1.1-1

986 1000 actuating shaft (with 25 tooth 31tooth chain roller) XWP260G3

987 contact roller (with roller) 10part XAA332X1*

988 escalator overhaul box cable L=25m sidewalk XAA26220AA4

989 escalator overhaul box cable L=9m XAA26220AA5

990 filter 42TDVST2 XAA657H2

991 75TDVST2 filter XAA657H4

992 1000UF capacitance

993 escalator overhaul plug XAA618AX1

994 edge warping guide plate pack parts XWP213E3

995 used in side work entrance outside decorate XWP262C9

996 entrance decorate XWO262C7

997 stainless steel entrance decorate XWP262C3

998 leading edge board (middle board/508step) XAA457BX1

999 leading edge board (comb 508step) XAA453AG1

1000 sidewalk long sleeve XAA81H1

1001 sidewalk shirtsleeve XAA81J1

1002 bearing direr XAA304AT1

1003 toe guard M=800 XCA281G3

1004 compensating chain direct system (metallic conduit) XAA392D1

1005 step A set of hanging scrolls prevention XAA316CY1

1006 down R brush bracket XAA402QQ1/2

1007 straight line brush bracket XAA402QM1

1008 HOLDERPROFOLE brush proximate matter GAA402CES1

1009 up R brush bracket XAA402SR1/2

1010 ENDCAP tip brush proximate matter GAA273WJ1

1011 BRUSH head brush GAA241G1/2

1012 flat bed flashboard bracket XBA347PP1

1013 sidewalk main wheel

1014 electromagnet MFZ1-4.5 XAA233D1

1015 bed junction box XAA308FV1

1016 core Shock absorption plate XAT997A15

1017 step baffle XAA386AJK

1018 step baffle 1000 sidewalk XAA386APZ

1019 railing test the speed sensor XAA177CD1

1020 rope clamp XAA20650B

1021 lower extreme place skirting XAA438SJ21-OUTDOOR

1022 down equipment room switch board in common usage electrical element XAA26202AQ3

1023 angle modulation bracket XAA417AH3

1024 railing to drive -third class horizontal ladder XWP260F25

1025 sill module 1800 Stroke double XBA426L7

1026 landing door system M=1800 Stroke double XWP210BV1

1027 protective guard 2pcs XAA24030A1

1028 protective guard 3PCS XAA24030A2

1029 VFBDS control box XAA308BJ1

1030 SELCON swing door control box XAA24350AD2

1031 operation 21VFBR27 button (Home-made) 10/10 XAA313H10

1032 operation XHW5/5 XAA25000C16

1033 GEN2 car top wire connector XAA25402A1

1034 take off the brake helper ACVV XHW155A1

1035 step bracket FT30°C FT11-7(35°C0103-10)

1036 swing door system (DO2000M=900MM)

1037 swing door system (XRDSM=900MM) without DISS

1038 swing door system (XRDS in common usage pieces) XAA27076F

1039 car (1600*1600MM spray-paint)

1040 Double folding door pocket (1800 stainless steel)

1041 door pocket (Big B style . stainless steel)

1042 door pocket (stainless steel M=900MM) XAA23141A49A439

1043 door pocket (little spray-paint M=900MM)

1044 Double folding car (stainless steel M=1500

1045 Double fold the hall door fastening piece XWP210FC1

1046 Double folding car M=1500

1047 Double folding medicine ladder marks stainless steel car XWP211CS21(OP=1500*2400)

1048 Double folding door (stainless steel M=1500) XWP210EK9

1049 Stroke double folding door – right shutter M=2600 XAA413AC45

1050 Stroke double fold hairline stainless steel XWP210EQ13(2400*2400)

1051 Stroke double folding elevator door XWP211DQ15(OP=2600*2600)

1052 Stroke door (stainless steel) M=900

1053 Stroke type door lamp square tube M=900stainless steel

1054 Stroke door (stainless steel) M=900 XWP210EY3

1055 White mirror stainless steel Hall door (bare door) XWP210EZ12-1(OP=900)

1056 Titanium mirror stainless steel Hall door (bare door) XWP210FB9-1(OP=900)

1057 Stroke door (iron plate) M=900

1058 REM RMON XAA21200B1

1059 Stroke double fold door OP=1800HH=2100 XWP210ES7

1060 Stroke double fold door cover HH=2100OP=1800 XAA23195D22A

1061 switch board (FO package 11KW) XWP100AT3

1062 switch board (STAR-11KW) XAA21290BA3

1063 switch board (STAR-15KW) XAA21290BA5

1064 switch board (STAR-CON90A)

1065 switch board (STAR-CON120A)

1066 switch board (OH5000) 11KW

1067 switch board (escalator B-package) XWP150A2

1068 switch board 300VF90A XAA21290K1

1069 MCS220-GEN2 norm switch board (OPT2) GAA21000BY1

1070 508escalator . Sidewalk frequency conversion switch board XAA26202AN6

1071 508escalator.Sidewalk norm switch board XAA26202AN7

1072 Traction machine (without the tooth) 9.5KW XAA20220A1

1073 without the tooth traction machine 6KW XAA20221A220

1074 Traction machine 13VTR11KW D13VTR109

1075 Traction machine 13VTR14KW D134VTR111

1076 Traction machine 160VAT15KW TAB20003A361

1077 Traction machine 16VEC11.7KW XAA20010A2

1078 Traction machine 17CT XAA20021S3

1079 Traction machine 17CT XAA20021S2

1080 Traction machine 18ATF TAD20000A539

1081 Traction machine 18ATF D18ATF102

1082 Traction machine ECH3 GAA20401C/11

1083 Traction machine ECH3 GAA20401C/8

1084 Escalator Traction machine 16VEC XAA2001A1.A2

1085 Escalator Traction machine EC2-7 9.5KW XAA20401A5

1086 Escalator Traction machine EC-SW 7.5KW XAA20400B1

1087 Escalator Traction machine EC-SW 9.5KW XAA20400B2

1088 Traction machine 60HT Power 30KW XAA2001AE16

1089 Traction machine 60HT Power 15KW XAA2001AE12

1090 GEN2-R1 Traction machine AAA20220AK5

1091 lifeline

1092 lifeline bracket

1093 summer work clothes

1094 shorting stub

1095 triangle lock label XAA102DP1

1096 saddlebag

1097 squiggling tool XWH260C2

1098 creep age protector XWH260C3

1099 car door retainer

1100 escalator opt-electrical XAA177ES1

1101 car top junction box XAA24830E1

1102 fireman box XAA23851B1A439

1103 fireman box (the newest) XAA23851D10

1104 time limited XS1-25(电碰吸铁) XAA20300E1

1105 cooler XAA713B2

1106 cooler digital display temperature controller XWL616A1

1107 piezoelectric type sensor GAA177GZ1

1108 Siemens trophies protector XAA613AX1

1109 fag end shield XAA384HF1

1110 metal strip detergent $X/VP-420540

1111 escalator Connect the tubing 2.6m XAA134D10

1112 annex arrester (electromagnetic arrester) XAA26220E1

1113 escalator with magnetic white riding wheel GAA456DK1

1114 508 escalator The partial article GAA385GF1

1115 STAR escalator the partial article XAA385A1

1116 multifunction upright post (with traffic flow rate light) XAA26620A1

1117 VF-7Fswing door transducer XAA622AB1

1118 68#resistance to wear hydraulic medium XWQ284A1

1119 508 escalator inlet inside (stainless steel) XAA402VX9

1120 508 escalator inlet inside (stainless steel) XAA402VX10

1121 L-style bracket XAA283JD1 XAA286GL1

1122 LCBII plank plug-in XAA618AT3

1123 groceries step hall (with doorframe stainless steel) XAA23371A12

1124 groceries step hall (stainless steel) XAA412A12

1125 escalator middle prop up 250 high XAA26220F5

1126 new STAR.XOP entrance outer flank left XAA396X101

1127 new STAR.XOP entrance outer flank right XAA396X102

1128 new STAR escalator entrance inner side left XAA396W101

1129 new STAR escalator entrance inner side right XAA396W102

1130 new XOP entrance inner side left XAA396W105

1131 new XOP entrance inner side right XAA396W106

1132 chip yard (02CV640TO) SM-02-V3.2

1133 SM-02-EXT-V3.1

1134 RS5J2

1135 Bottomless box machine station lock, fire-fighting button box

1136 XIZIOTIS key power switch

1137 LAY37(PBC) key power switch

1138 OTIS steel casing limited power switch

1139 The wheel–jumpiness’ style;side walk XWP261B1

1140 508 step S style XAA50CF1

1141 down flat bed inside cover board XAA402TH5

1142 escalator proximate matter–8# backbone XAA50D1

1143 ARMASSEMBLY swing stem structure XAA288N9

1144 up flat bed inside cover board (439 material) XAA402TG17

1145 SL item inside cover board (439 material) 508escalator XAA402TJ997

1146 up R outside cover board508 XAA402WF49/50

1147 SL-outside cover board-panel strip XAA402DQ1

1148 up R skirt deck 439508 escalator XAA438K1

1149 up skirt deck 439 (508 escalator) XAA438SH1

1150 180 standard railing bracket XAA316ACL1

What is the Elevator PLC?

Elevator is an important means of transportation in modern buildings, which is related to the safety of people’s life and property How to improve the efficiency of elevator operation, reduce energy consumption of elevator, reduce mechanical wear and prolong the service life of elevator are all very important research topics. Elevator is a complete set of equipment used for fixed elevations in floors. It has characteristics of safe, reliable, comfortable, accurate, easy to operate and transportation efficiency. It consists of lifting traction system, guiding system, safety device and electric control system.

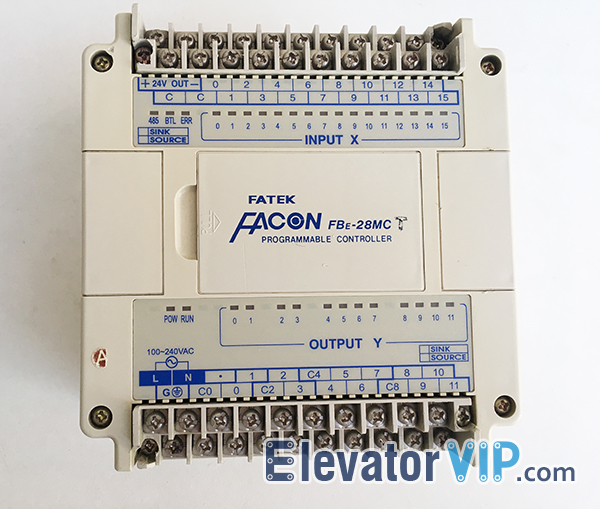

FATEK FACON FBE-28MCT PLC, FATEK FBE-28MCT Supplier, Cheap FATEK FBE-28MCT, FATEK FBE-28MCT Online, FBE-28MCT PROGRAMMABLE CONTROLLER, second-hand FBE-28MCT PLC, used FBE-28MCT PLC, wholesale FATEK PLC

At present the elevator control widely adopted two ways, one is using microcomputer as signal control unit, to complete the elevator signal acquisition, running status and the function set, realize automatic scheduling and collection operation function of the lift, drag the control are done by frequency converter; The second control method USES PLC (Programmable Logic Controller) instead of microcomputer to realize signal set selection control. In terms of control mode and performance, the two methods are not much different. Most domestic manufacturers choose the second method because of the small scale of production and the high cost of designing and manufacturing microcomputer control devices. PLC has high reliability and flexible program design. This design USES Mitsubishi, FX2 series PLC to control the displacement sensor of static magnetic grid to control the elevator flat layer.

How to use the elevator safely (Elevator Safety Knowledge)?

How to use the elevator safely (Elevator Safety Knowledge)

ONE- civilized waiting for the elevator

- Correctly press the up or down buttons at the door, not both at the same time. If you press the up or down button at the same time, it will make the elevator useless and waste the waiting time and electricity. When the elevator arrives, if there are multiple parallel elevators, the arrival lights of any one of them shine and the arrival bell rings, inviting you to wait at the entrance.

- After the elevator closes, passengers first go down and then go up. If any passengers come out of the car, you should stand on both sides to facilitate their evacuation and then enter the car.

- If the car is full, please wait patiently for the next elevator to arrive.

- When the elevator closes, don’t push your hands or other objects between the two doors

- In case of fire or other circumstances, people in the building shall evacuate through the stairway. Do not take the elevator, in case the power of the elevator is damaged, taking the elevator will be trapped in the car.

TWO- Correct access to the elevator car

- Get in and out of the car quickly and safely, do not stay at the door. Passengers standing at the door should leave the car first.

- Press the destination floor button correctly to ensure you can reach the aim floor.

- If the number of passengers in the car is moderate, you can move deep into the car to facilitate other passengers.

- Passengers with children need to take good care of children, and passengers with pets should prevent pets from moving alone.

- Keep a distance from the elevator door. When open and close door, special attention should be paid to prevent clothing or personal belongings from being crowded by the elevator door.

- If you need the elevator door to keep open, you should hold down the open button. If you need to carry your belongings, you can ask other passengers to hold down the open button

THREE- Take the elevator correctly

- Pay attention to check the elevator on the presence of << safety inspection >> label, and whether in the period of validity, don’t blind to take elevator such as do not conform to the requirements of the elevator equipment, to reflect the local Special Equipment Safety Supervision Department.

- Stand as close as possible to the wall of the car and put your hands on the car arms if elevator with it.

- Most elevator injuries occur at the door or in the hoistway. When the elevator fails, stay away from these two positions can keep you safe.

- The elevator door (the floor of the car door) is a very dangerous place and cannot stay for long

- Try to get in and out as quickly as possible, and don’t linger between the door and the door. Don’t lean against the elevator door or floor door while waiting and riding

- Gently press the call button or choose the operation box car floor layer button, indicator, quietly waiting for the elevator, don’t jump in the car, or with hard, sharp tap button or press the button again and again, and may not hinder the movement of the door by hand or by body

- Attention should be paid to the handling of articles. For transparent objects such as glass, when entering or leaving the car wearing thin long skirts, high heels and carrying umbrellas, careful attention should be paid to the accident caused by clamping.

- Do not carry inflammable, explosive or corrosive dangerous goods in the elevator.

Everything you should know about elevator brake

The elevator brake generates two-way electromagnetic thrust when electrified, which makes the brake mechanism separate from the rotating part of the motor. When the power is off, the electromagnetic force disappears. Under the action of the applied brake spring pressure, the friction-type brake of the electric loss brake is formed. It is mainly with escalators traction drive motor on formation of escalator with electromagnetic brake three-phase asynchronous motor, widely used in parking can achieve smooth and rapid start and brake when electricity safety.

Brake is an important safety device of elevator. Its safety and reliability is one of the important factors to ensure the elevator running safety.

The working principle of elevator brake

When the elevator is at rest, no current passes through the coil of the traction motor and the electromagnetic elevator brake. At this time, because there is no attraction between the electromagnetic iron core, the brake pad tightens the brake wheel under the action of brake spring pressure to ensure the motor does not rotate; The moment when the traction motor is electrically rotating, the coil in the brake electromagnet is connected with current at the same time, and the electromagnetic core is magnetized and absorbed rapidly, driving the brake arm to force its brake spring, the brake tile is opened and completely separated from the brake wheel, so that the elevator could be running; When the elevator car stop the required floor, the traction motor loses power, and the coil in the brake electromagnet also lost power , and the magnetic force in the electromagnetic core disappears rapidly. Then the core is reset by the brake arm under the action of the brake spring, make the brake tile hold the brake wheel again and the elevator stops running.

Useful conditions

- No more than 1000 m altitude, air relative humidity is not more than 80%, environment temperature + 40 ℃ ~ 15 ℃.

- There is no gas or dust in the surrounding environment that can corrode metal and break insulation.

- Insulation class B, protection class IP55, voltage fluctuation no more than + or – 5%.

- The working mode is S1 continuous working system.

- Working voltage AC220V/DC110V

Function of elevator brake

(1) It can make the elevator in operation stop the car automatically when the power is cut off.

(2) When the elevator stops running, the brake should be able to keep the car at rest and position unchanged under 125% rated load.

Installation method of Escalator Safety Brush

The escalator brush is also known as apron plate clamping device. It is fixed in the escalator handrail wall and class clearance above the dust, anti – clipping brush combination. There is a certain gap between steps and step with apron board, Generally the gap will not be greater than 4 mm, but in such a small gap also can make clothes or the child’s fingers, shoes divided into the damage, so install security brush for each escalator equipment is necessary.

How to use programming cable to communicate with FATEK FBE-28MCT PLC?

What is the PLC programming cable?

PLC Programming Cable is the communication cable, which is mainly used for communicating between PC and PLC. The functions of PLC programming cable: Programs can be uploaded and downloaded by PLC programming cable.

As everyone knows, PLCs (Programmable Logic Controllers) are used in many machines, in many industries which are used for controlling of machinery on factory assembly lines, amusement rides, or light fixtures. Now the FATEK FBE-28MCT PLCs are widely used in elevator & escalator control fields, but for novice how to use the PLC programming cable (Communication Cable) to communicate with FATEK FBE-28MCT PLC, it is difficult. Today, Elevator Vip is here to introduce some programming knowledge on FATEK FBE-28MCT PLC, let’s begin:

1. Prepare parts: Programming Cable, FATEK PLC (Model: FBE-28MCT), FATEK Programming Software (WinProLadder), and Programming Manual (Optional)

FATEK Communication Cable for FBE and FBS series

(USB-FB-232P0-150 USB TO RS232 ADAPTER FOR FATEK PLC FBE SERIES)

What is the reason for the deviation of escalator steps?

What is the reason for the deviation of escalator steps?

The escalator consists of steps traction chains, step guide rail system, drive device, tension device, and handrail device and metal structure. The structure includes: steps, kick plate, bracket and auxiliary wheel. Escalator is continuous work, therefore, in the stream of people concentrated in public places, shops, railway stations, airports, docks, the place such as buildings and underground railway station, to transport a large number of people in a shorter time, using the escalator has more advantageous than using intermittent working elevator.

The steps are integral and modular. The integral die casting is made of aluminum alloy with high precision, light weight and high processing speed. The modular echelon is composed of steps, kicking plate, supporting frame and other parts, with large weight and poor precision. It is a product of small die-casting capacity and is gradually replaced by integral echelon.

The steps move horizontally at the passenger entrance (for passengers to get on the stairs) and gradually form the steps. The steps fade away near the exit and the steps move horizontally again. These movements are realized by the steps of the main wheel and the auxiliary wheel respectively walking along different steps of the guide way.

Under the escalator room has two springs, is for adjusting the escalator cascade running deviation device, if can’t adjust well, that’s different cascade big chain long, need to change the big chains.

The escalator is generally inclined. A pedestrian standing on one end of an escalator will be automatically taken to the other end of the escalator and the steps will remain level all the way. Escalator step has with cascade synchronous moving in on both sides armrest, fu grip for users. Escalators can always walk in one direction, but most can be controlled by managers according to the needs of time, people and so on. Another type of pedestrian conveyance similar to escalators is the automatic walkway. The main difference between the two is that there are no steps on the automatic pedestrian path. Most only walk on the flat ground, or lean slightly.

The escalator consists of a stairway (variable plate conveyor) and an arm rest (deformed belt conveyor) on both sides. Its main components are cascade, traction chain and sprocket, guide rail system, the main drive system (including motor, speed reducer, brake, and the middle transmission links, etc.) drives main shaft, step and tension device, skeleton, comb plate, escalator handrail system and electrical system, etc. The staircase gradually forms a staircase after horizontal movement towards the passenger entrance (facilitating passengers to ascend the stairs). The steps close to the entrance gradually disappear and the steps move horizontally again. These movements are realized by the steps of the main wheel and the auxiliary wheel respectively walking along different steps of the guide way.

Buy FATEK FACON FBE-28MCT PLC for Replacement Elevator Control System

What is the PLC?

A programmable logic controller, PLC, or programmable controller is a digital computer used for automation of typically industrial electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or light fixtures. PLCs are used in many machines, in many industries.

What PLC can do for elevator?

PLC can be used to control various industrial machines, including the elevator and escalator control system. Today we are talking about SANYO elevator to use the FATEK FACON FBE-28MCT PROGRAMMABLE CONTROLLER to execute a control command. Also many clients ask Elevator Vip whether have the model FBE-28MCT? Yes, it is. Although this kind of PLC has been around for years, but as a professional who has been deeply involved in the elevator industry for many years, we have such capabilities for our clients to offer it. For details of model FBE-28MCT PLC, please refer to below:

Features of FATEK FBE-28MCT PLC

Parts Name: Programmable Logic Controller

PLC Model: FATEK FACON FBE-28MCT

Input power: 100V~240V AC, 50/60Hz, 30VA

Output power: 24V

Features on the case: indicator lights are 485, BTL, ERR, SINK, SOURCE, POW, and RUN.

Video of FBE-28MCT PLC parts:

Pictures of real FBE-28MCT PLC parts:

If you need Programming Software and User Manual (Fatek PLC Programming Manual) of FBE-28MCT PLC, please contact Elevator Vip.

We also can offer other models are FBE-20MA / 20MAT / FBE-20MC / 20MU / 20MUT / 28EA / 28MA / 28MU / 28MUC / 32EX / 40MA / 40MC / 40MU / FB-2DAS.

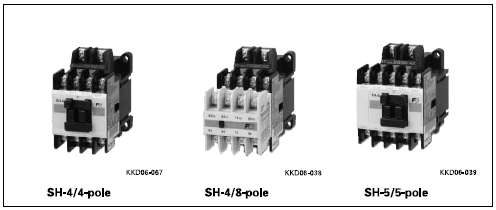

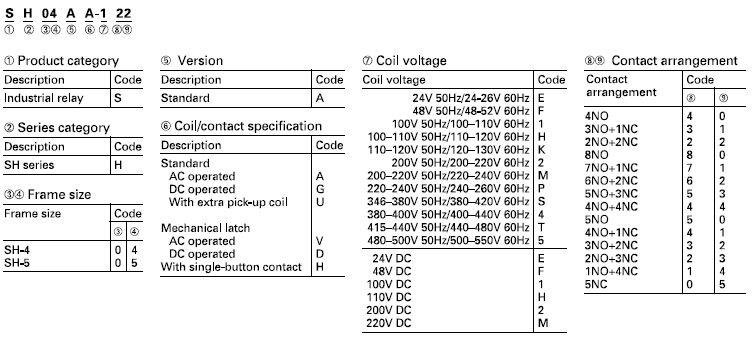

How to select SH series of Fuji industrial relays for elevator or escalator?

Relay is divided into AC Relay (voltage AC) and DC Relay (voltage DC), which is used in Electric power industry, due to relay device can be used to cut off main circuit quickly, therefore, it is often used for motor control.

For elevator industry, people usually use the relay to control circuit of elevator on and off, so it is a very important elevator parts. Nowadays, the world’s top 10 famous relay brands are: schneider, ABB, SIEMENS, Mitsubishi, Allen-Bradley, Fuji Electric, Sprecher+Schuh, OMRON, TE Connectivity, EATON. But today we are just discussing Fuji Electric Relay used in the elevator industry.

Bifurcated contacts with excellent electrical conductivity/Fuji SH-4 Relay, SH-5 Relay

Description of SH Series Relays:

SH series industrial relays are designed to increase contact reliability and make them easy to use.

The relays’ highly reliable, bifurcated contacts allow them to be used in low-level circuits of 5V, 3mA.

Various optional function units such as auxiliary contact blocks, coil surge suppression units can be added to the relays, allowing fast and field modification.

Fuji Relay Model Selection (SH Series)

Types and ratings

| Type | SH-4 | SH-5 | |||||||||||||||||||||||||||||||

| Pole (No. of contacts) | 4-pole | 8-pole | 5-pole | ||||||||||||||||||||||||||||||

| Contact arrangement | 4NO, 3NO+1NC, 2NO+2NC | 8NO, 7NO+1NC, 8NO+2NC 5NO+3NC, 4NO+4NC |

5NO, 4NO+1NC, 3NO+2NC 2NO+3NC, 1NO+4NC, 5NC |

||||||||||||||||||||||||||||||

| Thermal current (A) | 10 | 10 | 10 | ||||||||||||||||||||||||||||||

| Rated operational current (A) |

|

||||||||||||||||||||||||||||||||

| Standard operating coil voltage | 100V 50Hz/100-110V 60Hz, 200V 5OHz/200-220V 60Hz, 380V-400V 50Hz/400-440V 60Hz | ||||||||||||||||||||||||||||||||

| Mechanical durability Electrical durability (AC-15) |

10 million operations 500,000 operations (at operational current) |

||||||||||||||||||||||||||||||||

| Operating cycles per hour | 1,800 | ||||||||||||||||||||||||||||||||

| Ambient temperature | -5 to +50℃ | ||||||||||||||||||||||||||||||||

Ordering code system

What is the escalator anti-climbing device (Anti-climb Barriers)?

When the escalator is more than 12.5 cm adjacent to the wall, it should be on the escalator or automatic.

A blocking device installed at the upper and lower end of a sidewalk.

Generally, the escalator anti-climbing device on the market is mostly made of acrylic material, and its characteristics are as follows:

- The heat deformation temperature of ordinary acrylic sheets is about 100 degrees, and the continuous use temperature should not be higher than 90 degrees.

- Acrylic sheets are easy to generate static electricity and absorb dust. When cleaning with soft cotton cloth dip 1% soap water can be wiped.

- The surface hardness of acrylic sheets is equivalent to aluminum materials. When used or processed, please be careful to avoid surface scratches. If you get scratched,

The original glossy surface can be restored by polishing.

Installation necessity

In public elevators, there are no shortages of children chasing after play. Although many beside the escalators are “forbidden climbing play”, “children must be under adult supervision on” logo, but the installation of the elevator armrests prevent climbing, will also reduce the risk of accidents.

So to go against the wall adjacent to more than 12.5cm, on escalators or sidewalks, bottom department shall install block device, to prevent people from entering the outer cover plate area, thus fall accident, etc.

Method of use

If there is a risk of a person falling, appropriate measures should be taken to prevent the person from climbing onto the outside of the handrail device. In order to ensure this, escalators and moving sidewalks outside cover plate should be installed on the fortification climb the device (see right-hand chart), climbing device located above ground plane h9 (1000 + 50 mm), lower fellowship with outer cover plate, parallel to the outer cover plate on the direction of extension of l5 should not be less than 1000 mm in length, and shall ensure that within the scope of this length without stepping on foot.