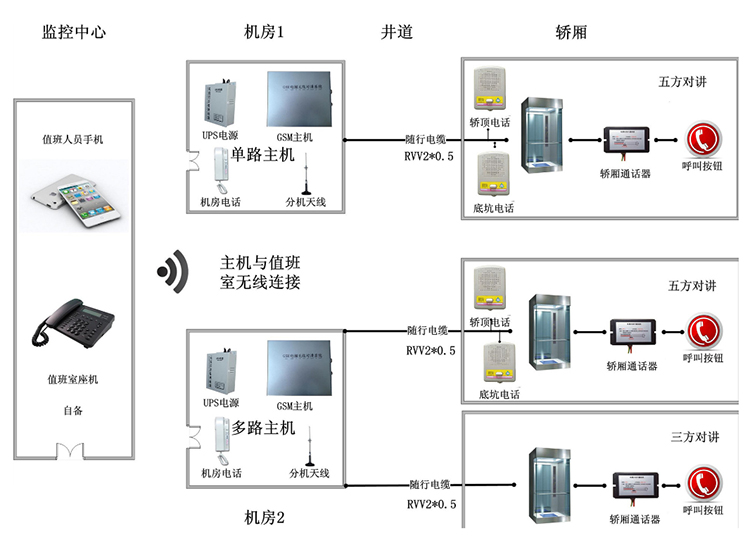

Five channel communication of elevator refers to the communication involved with the host of management center, car, machine room, top of the elevator and the bottom. The system can solve difficult problems and also carry out elevator maintenance and repair at ordinary times.

FM radio full-duplex elevator five channel system instructions:

It is a foreign relief system, which used for the elevator trapped or malfunction and it is also used as a communication system when the elevator maintenance. There are car inter-phone, elevator inter-phone (including machine room extension, car top extension, bottom pit extension) wireless extension and wireless host, the operation steps are as follows:

-

Car phone

1) In case of distress in the car, press the call button gently. The car phone will automatically call the host by voice without any other operation. The time of a two-way call after connecting is 60 seconds.

2) After the host receives the voice call, the on-duty personnel press the alarm button to conduct two-way communication with the call extension.

-

Elevator phone

1) Pick up the micro phone and talk to the car.

2) Press the “call” button to call the host of the duty room to talk to its implementation

GSM mobile network elevator five parties call system instructions:

also it is a foreign relief system, which used for the elevator trapped or malfunction, and also as a communication system, when the elevator maintenance. There are car sub-machine, handle sub-machine (including machine room sub-machine, car top sub-machine, bottom pit sub-machine) and wireless gateway. The operation steps are as follows:

-

Car extension branch phone

1) In case of distress in the car, press the call button gently. The car extension will automatically dial out the first phone number.

2) When the first phone number is dialed out, it can be hung up manually (press this call button lightly). Press the call button again and the car extension will dial out the second phone number automatically. The fifth inter-phone number is automatically dialed by the car extension.

3) Repeat steps 1 and 2. These five inter-phone Numbers can be redial. When the car extension dials the inter-phone number automatically, the inter-phone lift in the duty room will stop ringing and the car can be connected to make a call.

-

Elevator phone

1) Pick up the micro phone and talk to the car.

2) Press the “call” button to call the host of the duty room to talk to its implementation.

-

Duty room

1) When the call is received, the call can be picked up.

2) Call back in the duty room. Call back the mobile phone card number in the sub-machine and the corresponding car.

-

When any two parties are talking on the phone, either of them can join the product composition of the GSM three-party (five-party) intercom system.